LOWERING CUSTOMERS' TOTAL COST OF SHIELD OWNERSHIP

LOWERING CUSTOMERS' TOTAL COST OF SHIELD OWNERSHIP

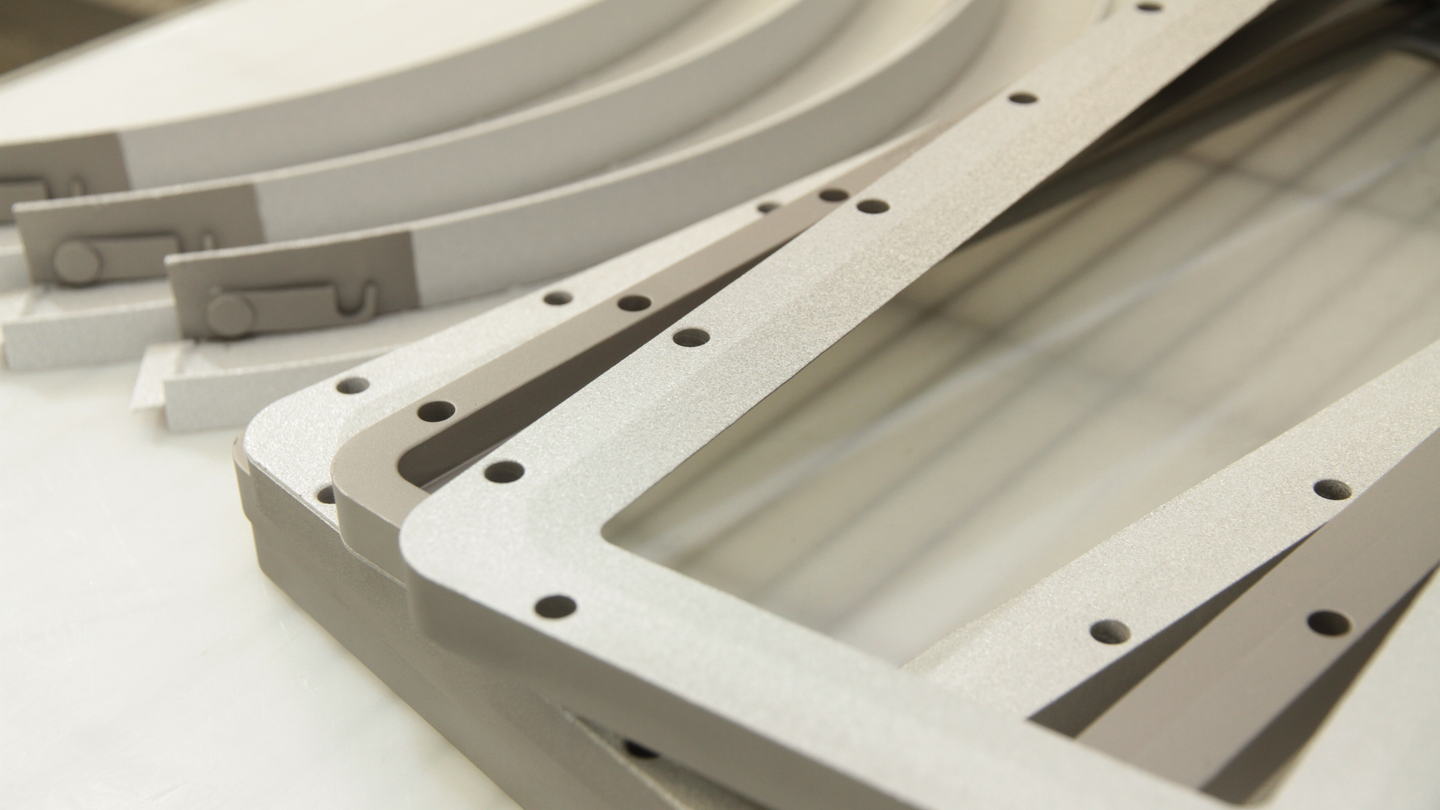

Our proprietary advanced surface coating extends shield life. That's especially true in particulate-sensitive PVD processes that deposit materials such as tungsten, tantalum or chromium. Coatings are applied using our aluminum twin wire arc spray coating (TWAS). TWAS creates a protective layer to ease deposition removal and minimize chamber particulate. The coating helps increase shield life by reducing cleaning cycles, ultimately lowering our customers' total cost of ownership. Materion partners with customers to develop process-specific texturing on shields. This optimizes tool up-time, reduces particulation, and extends preventative maintenance cycles.

ADVANCED TECHNOLOGIES AND SERVICE CAPABILITIES

ADVANCED TECHNOLOGIES AND SERVICE CAPABILITIES

Materion’ s parts cleaning technologies and service cprovide our customers with distinct competitive advantages. We recover the widest range of precious metals, including gold, platinum, palladium and silver to meet our customers’ chamber service needs.

- Chemical removal of depositions without aggressive mechanical procedures reduces cleaning times and extends cleaning intervals

- Internal capability to sample, assay, and recover precious metals from Shield Kits

- Deposition is removed into a form factor that is amenable to precious metals recovery. This results in the highest precious metal returns and fast settlements

- Cleaned parts are packaged to industry clean room ultra-high vacuum requirements with ISO Class 6/FED Class 1,000 or better clean rooms

- ISO 9001 & 14001 certified facilities and our analytical lab is ISO 17025 certified

- Our simple, streamlined maintenance logistics allow our customers to focus on their operation, not their manufacturing equipment

- Serving the semiconductor, data storage, wireless, LED, medical, defense/aerospace, photonics, life sciences, glass coating industries and more