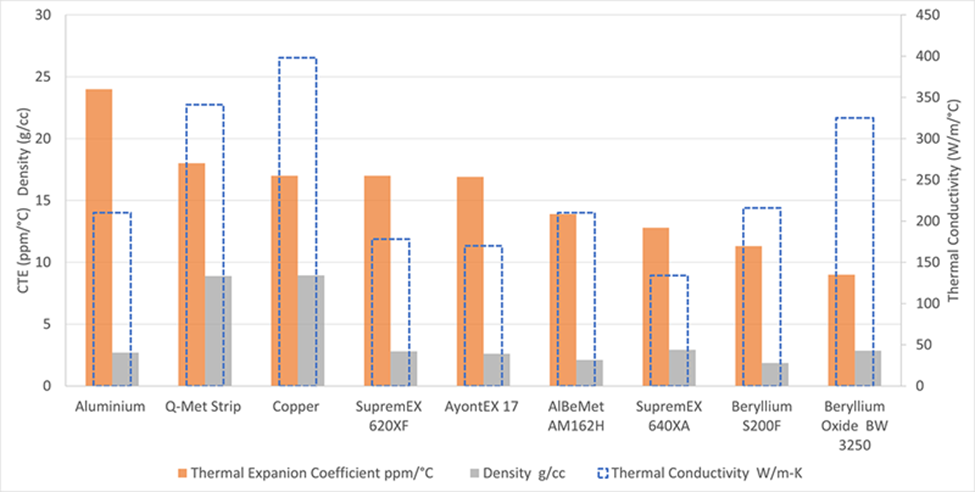

Thermal Materials - Summary of Expansion, Conductivity and Density

Materion’s advanced materials are used for thermal management in high-consequence defense equipment across multiple domains, equipment which cannot fail even under the most demanding circumstances. Thermal management solutions are also important for many other markets (including aerospace, automotive, EV and consumer electronics) where reliability, sustainability and life-cycle cost are paramount.

Thermal management in the context of this blog refers to designing systems that allow heat to be transported, stored or expelled in a manner that enables key system elements to operate and continue to operate within a specific temperature range. Controlling the temperature of critical components provides for their optimum performance. Thermal management is most often associated with microelectronics assemblies and systems in which elevated temperatures can significantly reduce system performance and even cause system failure. In general, the demand for increased power density, reduced size, greater reliability, and the ever-present need for lower costs have continued to increase the challenges for thermal management materials.

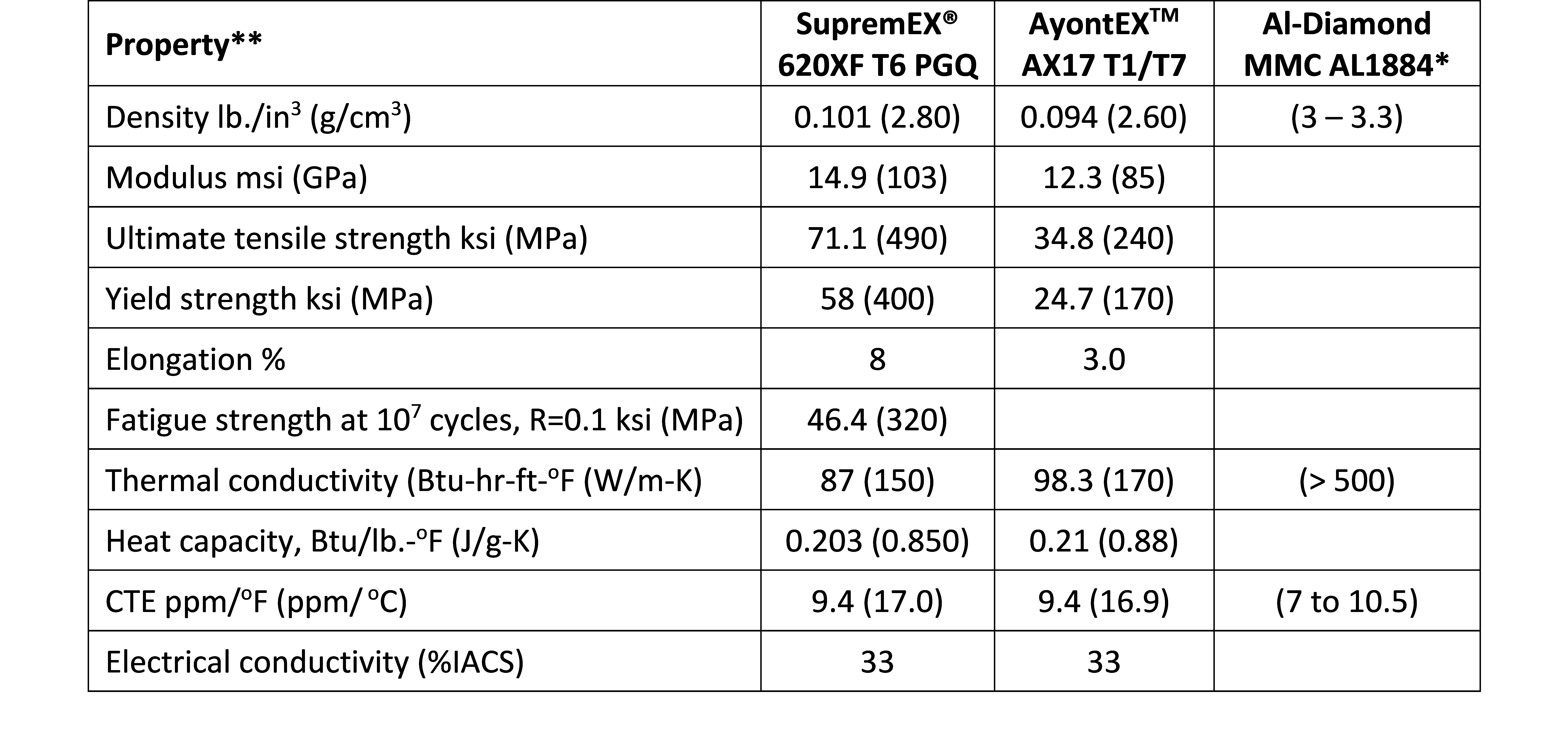

Thermal management materials include ceramics, metals, alloys, metal matrix composites (MMCs), laminates and even plastics, for some applications. While determining the material properties and characteristics needed for thermal management, note that thermal management applications have widely varying requirements that encompass many aspects of materials science. There are the obvious thermal properties – thermal conductivity, specific heat or heat capacity, CTE (coefficient of thermal expansion) and thermal diffusivity. Then there are additional considerations to take into account such as structural properties, stiffness, strength, fatigue strength and how these properties vary across a temperature range. These certainly can be important considerations for some applications, as can damping properties or frequency response.

Material processing characteristics such as machinability, hermiticity, solderability, suitability for brazing and other available joining techniques, along with whether the material can be nickel plated and/or CVD gold coated should also be considered. Is the material an electrical conductor or insulator? Is it magnetic or non-magnetic? Is it compatible with other materials, gasses or chemicals in the system?

As you can see from the above list of considerations – which is not compete – the selection of materials for thermal management is a complex problem. Not only does it require extensive knowledge of materials, but it is always a multidisciplinary problem set that may need input from physicists, chemists, structural, thermal and corrosion engineers, plus many others.

Below are some considerations and characteristics for a sample of thermal management materials used in defense applications:

Characteristics of Two Types of Beryllium Oxide Ceramics

*Information from Stanford Advanced Materials

*Information from Stanford Advanced Materials

Characteristics of Two Types of Metal Matrix Composites Manufactured via Powder Metallurgy

Characteristics of Copper Alloys and Copper MMCs

Many of our thermal management materials for defense applications are low density (less than 3 g/cm3), ideally suited to airborne and space applications. We also offer solutions that are not focused on low-density, including copper alloys and metal laminates.

Our team has many years of materials knowledge, and we understand the challenges of selecting suitable materials for thermal management. Our technical support team enjoys discussing options – our specialty is coming up with custom solutions for unique applications. You can contact them with questions at +1.800.375.4205.

** All material property values listed in the above tables are for reference only and should be considered typical values. The materials manufacturers or suppliers’ technical specification/data sheet should be used for property values associated with specific materials.