In an increasing number of engineering applications, materials are required to operate in magnetic fields. The critical requirements of such operation are that the disturbance to the magnetic field be small and that the material retain no remnant magnetism after exposure. Materials that exhibit these characteristics are termed magnetically transparent or, simply, nonmagnetic. Copper beryllium alloys are frequently specified because they possess these nonmagnetic characteristics. In addition, copper beryllium offers high strength, toughness, and conductivity from cryogenic to above room temperature.

There are two classes of copper beryllium alloys: High Strength Copper Beryllium has the highest strength of any copper alloy and offers good thermal and electrical conductivities. Depending on the product form, the tensile strength can exceed 200,000 psi (140 kg/mm2), with an electrical conductivity in the range of 18-25% IACS, and a thermal conductivity of 60 BTU/ft·hr·°F (105 W/m·K). The High Conductivity Copper Beryllium alloys offer considerably better conductivity’s (50-60% IACS and 145 BTU/ft·hr·°F, 250 W/m·K) at a moderate strength level of about 120,000 psi (85 kg/mm2). Materion’s copper beryllium alloys are available as strip, rod, wire, plate, bar, tube, and casting ingot. The common high strength copper beryllium alloys are Alloys 25 and 165 (UNS C17200 and C17000); the high conductivity alloys are Alloys 3 and 10 (UNS C17510 and C17500).

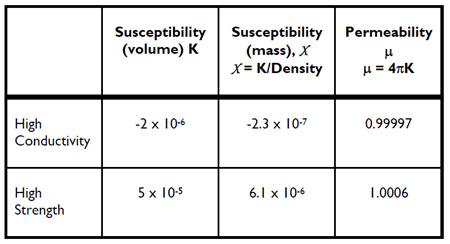

Nonmagnetic metals are either paramagnetic or diamagnetic, depending upon the occupancy of the metal’s electron shells. In paramagnetic metals, the individual atoms possess a net magnetic moment but their random orientations result in zero net magnetization for a group of atoms. In a magnetic field these random atomic moments become partially aligned and have a slightly greater flux than the applied magnetic field. Paramagnetic materials have a positive susceptibility and a permeability greater than 1. In diamagnetic materials, the balance in atomic magnetic effects, resulting in zero atomic magnetic moment, is disturbed by the presence of a magnetic field producing a small opposing field. Diamagnetic materials have a negative magnetic susceptibility and permeability’s slightly less than 1. The high conductivity copper beryllium alloys are diamagnetic and have magnetic behavior similar to metallic copper. The high strength alloys, typical of most copper alloys, are weakly paramagnetic. Figure 1 lists copper beryllium’s typical magnetic properties as determined by the Gouy balance and vibrating sample magnetometry techniques.

Figure 1. Magnetic Properties (cgs units at 1000 Gauss) of Copper Beryllium.

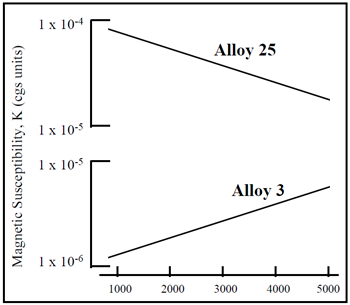

Copper beryllium’s magnetic properties are constant over the entire strength range of the alloys. The magnetic properties are not temperature dependent from liquid helium to above room temperature. Figure 2 shows that magnetic field strength has a minor influence on magnetic properties of copper beryllium.

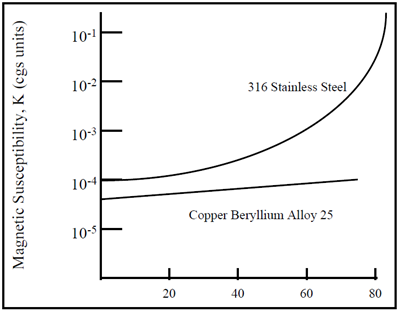

Cold work or plastic deformation does not change the magnetic performance of copper beryllium. As a result of cold work, which may occur in service, some nonmagnetic austenitic stainless steels transform to ferromagnetic martensite. As shown in Figure 3, deformation increases the susceptibility of the stainless steel while it has no effect on copper beryllium. The localized deformation from machining or surface abuse can result in magnetic hot spots in stainless steel. The martensitic transformation in stainless steels occurs more readily at low temperatures. Accumulated strains, resulting from thermal cycling to low temperature, can cause a deterioration in nonmagnetic quality in stainless steel. This is not a problem with copper beryllium.

Figure 2. Effect of field strength on the magnetic susceptibility (volume) of Copper Beryllium.

Because of the combination of strength and low magnetic susceptibility, the high strength copper beryllium applications range from small springs and electronic connectors for low frequency/low signal communication to large diameter tubes which serve as instrument housings for magnetic survey equipment. The high conductivity copper beryllium alloys are used in magnet structural applications (cryogenic and room temperature) where a high conductivity, moderate strength, nonmagnetic material is required.

Figure 3. Effect of deformation on magnetic susceptibility of copper beryllium and stainless steel.

Thanks for joining me for another edition of In Our Element. For ongoing industry updates, connect with me on LinkedIn.