In the ever-evolving landscape of material science, clad metals stand out as a revolutionary innovation that combines the best attributes of different metals and alloys. This article is the introduction to a series about clad metals that will discuss how what they are, how they’re made, their benefits, and their applications.

By employing advanced metallurgical bonding techniques such as plating, welding, roll bonding, and heat treatment, clad metals bring together materials with contrasting properties to create a unified product with a completely new set of capabilities. This unique amalgamation allows for the development of materials that can meet the stringent demands of modern engineering and industrial applications.

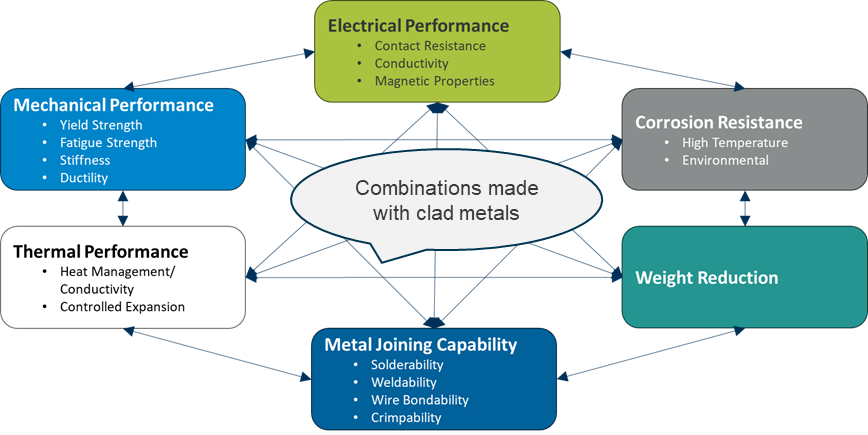

Clad metals are engineered to harness the strengths of their constituent materials, resulting in combinations that were previously thought to be incompatible. For instance, imagine a material that offers both high electrical conductivity and high strength, or one that combines high thermal conductivity with exceptional stiffness. These seemingly conflicting properties can be unified into a single material which enables a completely new set of properties (see also Figure 1).

The versatility of clad metals opens a plethora of possibilities across various industries. Here are some compelling examples of the unique property combinations that clad metals can achieve:

Figure 1. Combinations made with clad metals to generate new, unique property sets.

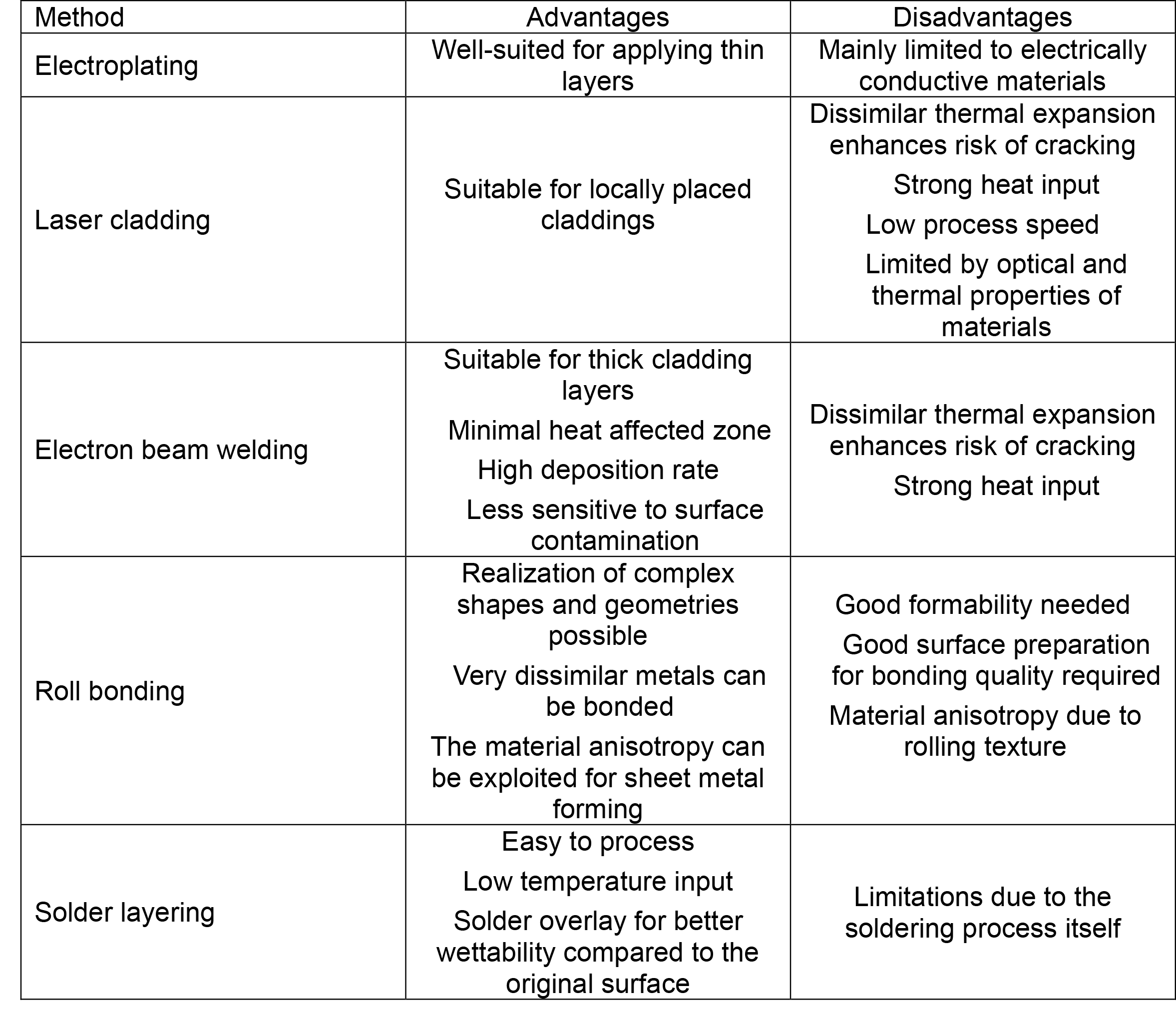

Two aspects are particularly important for clad metals: the selection of the material components and the process of metallurgical bonding (electroplating, laser or electron beam welding or roll bonding). The material components are chosen based on which properties are needed in the final material.

Several aspects are relevant when choosing the appropriate cladding method:

Some of these aspects are summarized in Table 1.

Table 1. Advantages and disadvantages of different cladding methods.

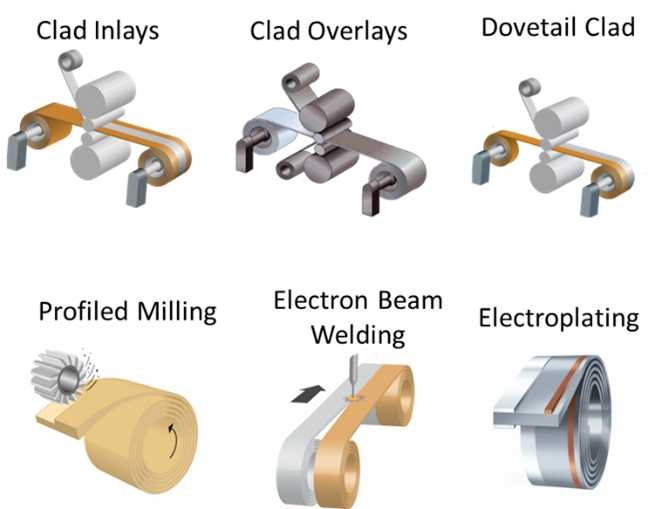

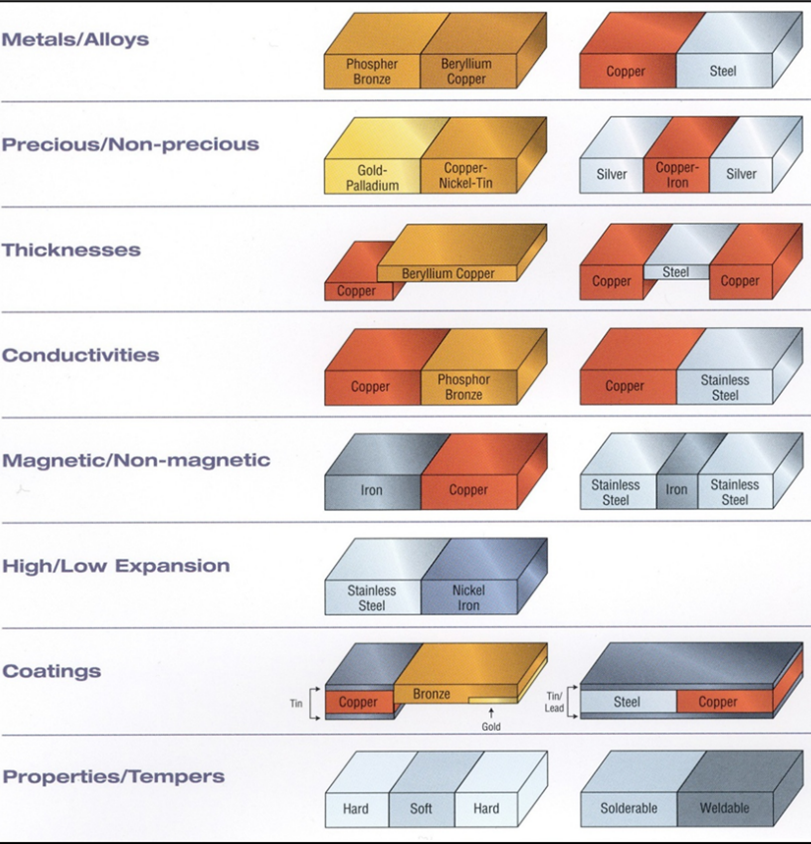

This means that many possible combinations are conceivable. The combination of metals and alloys in specific designs with different cladding processes open a wide universe of new solutions for demanding applications (Figures 2 and 3).

Figure 2. Geometrical solutions for clad metals.

Figure 3. Clad metal combinations for different sets of properties.

Due to their outstanding performance, clad metals are essential for existing applications like connectors for batteries, heat spreaders and heat sinks. They are also proving to be extremely effective for new applications such as components for hydrolyzers and fuel cells.

As we delve deeper into the world of clad metals, we will explore the various methods of production, the specific applications they are suited for, and the future potential of this groundbreaking technology. Join us on this journey to discover how clad metals are transforming industries and pushing the boundaries of what is possible in material science.

Learn more about Materion's family of clad metals on our website.