A fatigue failure is a fracture of a component under repeated or cyclical loading at stress levels insufficient to cause fracture in a single cycle. Most people intuitively understand the concept of fatigue failures, even without engineering backgrounds. When a person bends a paper clip or any other piece of wire back and forth until it breaks, they are deliberately inducing a fatigue failure.

Sometimes, such failures may only be minor inconveniences. A light bulb may suddenly burn out after many on-off cycles. The faucet handle on the kitchen sink may suddenly break off in your hand. These everyday events can be initially surprising and mildly annoying but are hardly newsworthy. Items are expected to “wear out” over time and break. Other times, fatigue failures can be major catastrophes, such as when they cause airplanes to crash or bridges to collapse. There are also times when a part never experiences a failure, or at least does not fail during its service life. Exactly if, and when, such a failure will occur is unknown, although it is possible to design a component with reasonable confidence that it will not fail during its expected life.

One of the most important questions a designer can ask is, “How long can I expect this component to last?” Parts can be designed to last longer, but at increased cost. Parts can also be made less expensively, but at a penalty of reduced durability. Making a part cheaply may save initial costs, but having it fail during the warranty period could cause the costs of covering the warranty failures to skyrocket. A failure after the warranty period has expired but during the expected useful life can be equally frustrating for consumers and may end up costing repeat business. On the other hand, designing a device to last for 500 years makes no sense when the expected service life is only 2 or 3 years, since odds are that few people would be able to afford it. Designing for fatigue therefore requires determining the appropriate trade-off between manufacturing cost and the service life expected by the consumer.

A stress-strain curve describes how a material behaves as it is fractured in one loading cycle, from zero stress and strain through yielding and ultimately fracture. However, in cyclic loading fracture is possible at stresses well below the ultimate strength and even below the yield strength. Tiny defects that are present in all materials can, over many stress cycles of stress application, grow into large cracks that weaken the structure and ultimately lead to sudden and sometimes dramatic fracture. These are known as fatigue failures.

Fatigue is a cumulative process, which may or may not result in a failure. Fatigue progresses through three stages. The first is called the crack nucleation stage. Every product made from virtually every material has tiny defects that are virtually undetectable by inspection. (After all, no part is ever completely perfect.) These defects could be voids or inclusions in the base metal, tiny scratches, cracks, burrs from machining or forming processes, etc. After a series of cycles of stress application, the defect may develop into a tiny crack. Sometimes, even a sharp notch or corner in a highly stressed area on a part can concentrate enough stress to generate a minute crack at the tip.

The second stage of the fatigue process is the crack propagation stage. At each stress cycle, stress is concentrated at the crack tip. The material will undergo localized yielding, and the crack will slightly enlarge. At each subsequent loading cycle, the crack will be slightly larger than in the previous cycle, resulting in a greater amount of stress concentration. As the crack grows, the cross section available to carry the load decreases as well. It is important to note that the tip of crack can experience plastic deformation as it expands, even if the calculated stress in the overall part is well below the yield strength. It is the concentrated stress at the crack tip that governs whether the crack will advance. Another important point to note is that crack propagation is not inevitable and will not occur if the stress in the material is low enough.

Eventually, a crack may become so large that the overall stress in the part will exceed the fracture strength of the material, and the part will experience the third stage of fatigue - sudden fracture. There may be no outward sign of an impending failure before it is too late, since the cracks typically progress internally, and if they appear on the outer surface at all, may only be as nearly invisible hairline cracks.

For a fatigue crack to propagate, the stresses in the material must be sufficient, cyclic, and tensile. This means that the localized stress increases to a high tension, decreases, and increases again repeatedly. This could be due to a load of varying intensity, or even a load of constant magnitude but varying direction. Any source of sufficient stress can cause crack propagation, whether it is due to applied forces, pressures, impacts, transmitted vibration, thermal expansion, resistive heating from carrying electrical currents, etc. The stress can be applied in pure tension, bending, torsion, or in a combined load state.

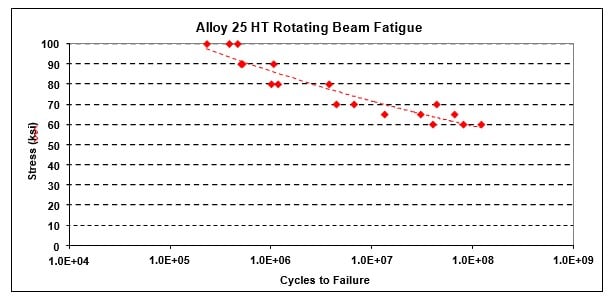

A material’s fatigue performance can be characterized by an S-N diagram. In this case, S refers to applied stress and N refers to the number of cycles to failure at each stress level. To obtain the diagram, a test specimen would be cyclically loaded to a particular stress level, and the number of cycles to failure would be recorded. After a number of tests, the data would be plotted on a chart, such as the typical chart shown below in Figure 1.

Figure 1. S-N Diagram Showing Fatigue Failure of Alloy 25 HT

As we have learned, fatigue is a progressive process and failure is not inevitable. With a better understanding of the science behind the fatigue process, more informed decisions can be made regarding material choice, expected service life and ultimately product design.

Learn more about Alloy 25 on our website.

Thanks for joining us for another edition of In Our Element. For ongoing industry updates, connect with us on LinkedIn.