One key to the advancement of many technologies is the ability to reduce the feature size, such as CMOS gate length or thin film head track width, of the devices produced. When working with thin film deposition processes, a reduction in feature sizes requires thinner deposited film layers. For example, in the Thin Film Head industry, some layers are less than 20 angstroms thick! So, as feature size gets smaller, and layers get thinner, the film thickness uniformity of the deposited layers becomes a major factor in product yields. Additionally, in magnetron sputtering systems, uniform magnetic penetration of the target can affect the uniformity of the deposited film, especially when working with ferromagnetic materials.

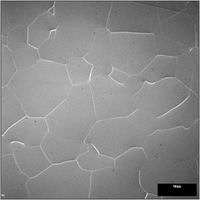

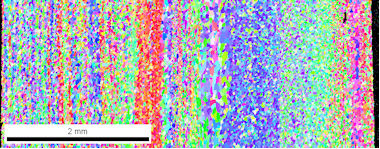

At Materion, with our decades of experience in manufacturing PVD materials, we continually optimize our manufacturing processes to provide our customers with materials that enable consistent, superior film thickness uniformity. To enable this high level of uniformity, it is crucial to take grain size and overall material microstructure into account. Materion accomplishes this through precise control of not only the size and shape of the grains (Figure 3), but also their random orientation. (Figures 1 & 2). This tight control needs to exist not only across the face of a target, but also through the thickness of every target in each and every lot produced.

Regardless of the PVD material you use, Materion has the capability to manufacture it to optimal film thickness uniformity. Whether vacuum melting, sintering, HIP or CIP is the best material fabrication method for your requirements, Materion offers the smartest solution. Additionally, we employ all types of hot and cold rolling or forging to deliver a target with a superior microstructure. Our expertise in thin film uniformity provides uniform quality results across every lot, because we understand that this is of paramount importance to your business success.

When you need sputtering targets that provide consistent performance from target-to-target and through the life of each target, Materion delivers best in class materials that enable excellent thin film characteristics, and allow us to remain your first choice. Contact your local Materion representative for more information.

Figure 1. EBSD of a Ta target thickness shows orientation “banding”

Figure 2. EBSD of Materion supplied Ta shows no orientation “banding”

Figure 3. Microstructure for a Cu based ternary alloy