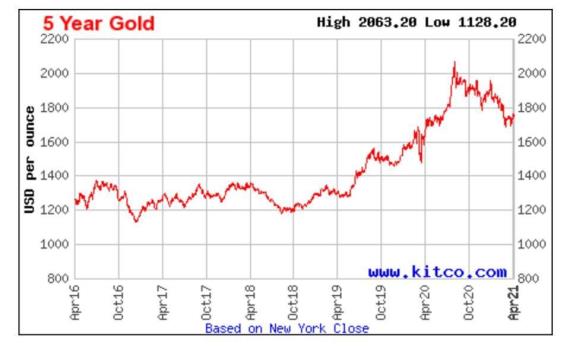

Image credit by https://www.kitco.com/

It's no secret the price of gold has risen considerably over the last 5 years. Based on the current market price, the price of gold increased more than 50% since 2016. The price of gold is presently influenced by investors who buy gold as a hedge against inflation and recent debasement of fiat currencies like the US Dollar. Output by the world’s gold mines and from the recycling industry has not tracked linearly with increased demand. While most of the gold consumed world-wide is used either as an investment vehicle or for jewelry, Materion’s customers use high purity gold and gold alloys for a number of electronic applications. In the jewelry and investment markets, the price of gold-containing products is adjusted frequently, sometimes daily, in response to the market price. However, electronics and photonics companies who consume gold typically cannot pass along fluctuating market prices of gold to their customers on a daily basis. For example, manufacturers of products that contain thin film gold layers do not charge their customers as gold prices rise or fall. Any cost as a result of rising gold prices charged by their suppliers is absorbed by the device manufacturer until the next opportunity arises to negotiate the price of their devices.

Since the price of gold is beyond the control of Materion or its customers, many electronics and photonics manufacturers have accelerated development efforts to reduce or “design-out” gold and gold-containing alloys. The "design-out" of gold is difficult because of the many unique and technical advantages gold provides including: corrosion resistance, compatibility with other semiconductor materials, high ductility and good thermal and electrical conductivity. Substitution or reduction of gold inevitably requires an investment in added processing steps and reliability studies, but as long as the market price of gold is high, these added efforts are cost justified.

In addition to designing products to use less gold, Materion works with some of its industrial gold consumers to minimize cost by managing the entire gold lifecycle. Customers can buy gold to put into an account, which makes it easy to return spent PVD targets or other reclaimed gold back for gold credit. The cycle begins by Materion selling a gold sputtering target or evaporation slug to the customer. In the course of using these input materials, gold will be deposited onto surfaces inside the vacuum chamber other than the product wafers. Materion’s shield services business or precision parts cleaning service offers thorough cleaning of PVD shield kits, removal of the precious metals from the kit surfaces, refining the reclaimed metals, and crediting the value of the metals back to the customer’s account. When PVD targets are spent, Materion will take back and recycle the target, again crediting the customer’s account for the value of the reclaimed gold. For very large customers of gold, Materion has placed an employee at the customer’s location to manage the entire lifecycle of precious metals for the customer.

Below is a list of gold products and the steps currently being taken by customers to reduce or eliminate gold for additional cost savings.

At RF frequencies, electrons penetrate only a shallow skin of the electrical conductor. Therefore, the outermost surface of a material conducting RF electrons must have a high electrical conductivity, and this conductivity must not drift over time. Since gold is easy to plate and maintains a high electrical conductivity, and also will not oxidize, gold-plated RF packages have been standard since the invention of the RF power transistors back in the 1960’s. Additionally, the gold-plating on the package is dissolved with Si from the backside of the Si chip to create AuSi eutectic solder in-situ for die attach. Materion and its customers are working on a variety of approaches to reduce or eliminate gold on the package for cost savings.

80:20 AuSn eutectic is a lead-free solder with a liquidus temperature of 280 degrees C. AuSn is used for die attach and hermetic lid sealing. The AuSn preforms and ribbon have the advantage of not requiring flux reflowed in an inert atmosphere.

To help customers reduce volume of gold being used, where possible, such as for die attach, Materion has developed thinner versions of AuSn. With recent manufacturing developments, eutectic solder can roll AuSn down to a thickness of 0.0007”, and 0.0005” (13 µm), in special circumstances. Materion can also manufacture PVD materials that can deposit AuSn solder onto the backside of wafers. Thin film deposited layers of AuSn can be made much thinner than 0.0005” (13 µm) and are typically 2 – 8 µm thick. Additionally, Materion offers AuSn sputtering targets whose composition is tailored to compensate for the unequal sputter rates of Au and Sn. The sputter-deposited film has approximately 80:20 ratio of Au to Sn in order to achieve the desired liquidus temperature. High purity Au and Sn evaporation slugs are also available, enabling co-evaporation or alternative evaporation of Au and Sn. PVD deposition of AuSn solder on the backside of wafers is currently employed by certain LED and RF device manufacturers.

Materion offers a range of solders with liquidus temperatures near 280 degrees C. If a lead-free solder is required, Materion offers SnSb alloys with a liquidus temperature ranging from 235 degrees C - 240 C, depending on the alloy composition.

Thin film gold has been a standard metallization layer on GaAs, InP and GaN-based compound semiconductor devices for over 35 years. Au is used to coat or fill vias, as a conductive trace material, and as a backside metallization. Today, most GaAs devices used for RF wireless communication (like cell phone power amplifiers) and GaN-alloy devices used for LEDs, contain ohmic contacts with a layer of gold. Researchers are working to develop ohmic contacts that are gold-free. Materion offers PVD consumables including Ti, Al, W, Au and many other metals that are widely used by the compound semiconductor industry.

Materion can improve electrical performance and reduce precious metal content through their unique electroplating and cladding capabilities. These technologies are able to selectively deposit ultra-thin Au layers in combination with high performing complex Pd based alloys. Materion has also developed specialized clad Ag solutions for high cycle, high energy EV connections, and all of these highly engineered electrical contact surfaces can be combined with Materion’s copper-based substrate alloys. This allows designers to create an optimized mechanical and electrical material for even the most demanding component. Materion’s iON Connector family of solutions offers specific value propositions for a variety of applications. Designs are available specifically for high temperature applications as well as corrosive environments and high vibration applications and provide solutions in automotive, industrial and consumer electronics markets around the world.