Electrical connectors form critical linkages between components of electrical systems. Reliability is vital and requires stable terminal material systems to provide long-term performance even under harsh environments. Materion's clad metal and electroplating technologies combine high stability contact materials with spring alloys, creating reliable electrical terminal materials ready for high throughput stamping and molding operations.

We provide electrical connector materials solutions to address challenges such as high vibration, high current, high temperature and cost.

ELECTROPLATED CONNECTOR MATERIALS

Electrical connectors depend on stable contact materials to provide reliable long-term performance with minimal signal distortion. Electroplating is a widely accepted process to apply these contact finishes for high volume manufacturing, and we have more than 30 years of experience producing high quality reel-to-reel electroplated products. Working with high performance copper alloys, stainless steels and even aluminum-based metals, our electroplating technologies apply precision layers of nickel, tin, silver and gold for stable contact surfaces.

NOBLE METAL CONTACTS

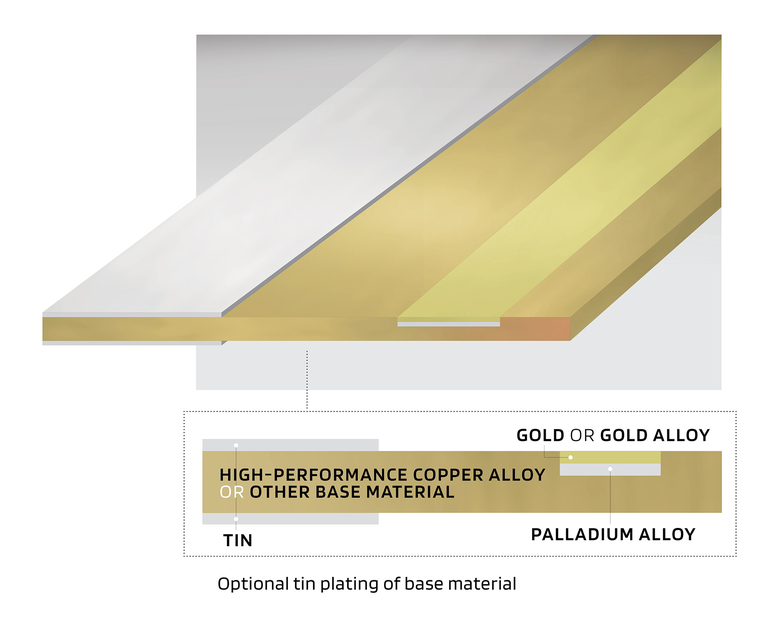

Precious metals are commonly used in electrical connector applications for their resistance to tarnish and stability in unfavorable environments. Typically, these are silver, palladium or hard gold-based—or they may also be multilayer systems such as gold-capped palladium to reduce precious metal usage. Advanced IPC controls on our selective plating and spot plating lines enable precision placement of precious metals to produce high-quality materials.

TIN CONTACTS

Tin is a widely used electrical contact finish due to its malleability and the ability to easily displace tin oxide at the mating surfaces. We offer both matte and bright tin as overall plating or in selective stripes. Additionally, tin plating can be combined with noble metal contacts to provide corrosion resistance to the connector spring alloy.

Electroplating is the process technology of choice for the majority of connector and terminal materials but may not be appropriate for every application. When performance requirements stretch the limits of what electroplating can offer, we recommend our iON Connector solutions for harsh environments.

ELECTRICAL AND ELECTRONIC ION CONNECTOR MATERIALS FOR HARSH ENVIRONMENTS

iON connector materials are engineered alternatives to electroplated contact surfaces with contacts that are metallurgically clad into the connector. Using alloys specifically designed for the task, iON clad connectors improve temperature, wear and corrosion performance while reducing exposure to expensive precious metals.

The alloy systems used in iON connectors were developed with harsh conditions in mind. Whether the objective is gold replacement, high wear performance, high-temperature connectors, or corrosion-resistant contacts, these materials outperform electroplated systems. Custom solutions are also available depending on your challenge.

ION VS. GOLD AND PALLADIUM ELECTROPLATING

The improved performance properties are derived from the alloyed microstructure of iON materials. Manufactured as an inlay clad strip in copper spring alloys, iON connectors have fully dense structures that provide high temperature and corrosion resistant contacts.

With overall contact layer thicknesses down to 0.5 µm, iON materials can be drop-in replacements for electroplated gold and palladium systems. Each iON material is specifically formulated for its application.

| CONTACT FINISH | DESCRIPTION | APPLICATIONS |

|---|---|---|

| iON – GR | Composite alloy of silver and palladium with a noble gold enriched contact surface. | A low-cost replacement for hard gold electroplated connectors, with additional benefits of improved high temperature and high vibration stability. |

| iON – HW | Ultra-hard wrought nickel-palladium base layer with a gold enriched surface. | For maximum wear performance in applications with high vibration, sliding or make-break contacts. |

| iON – HT | Stable alloy system of silver-palladium-gold providing high hardness, nobility and supreme temperature stability. | For ultra-high temperature connector applications with exposures to temperatures up to 350°C. |

Benefits

- Long-term performance

- Handles high vibration, current & temperatures

Applications

- Electrical terminals