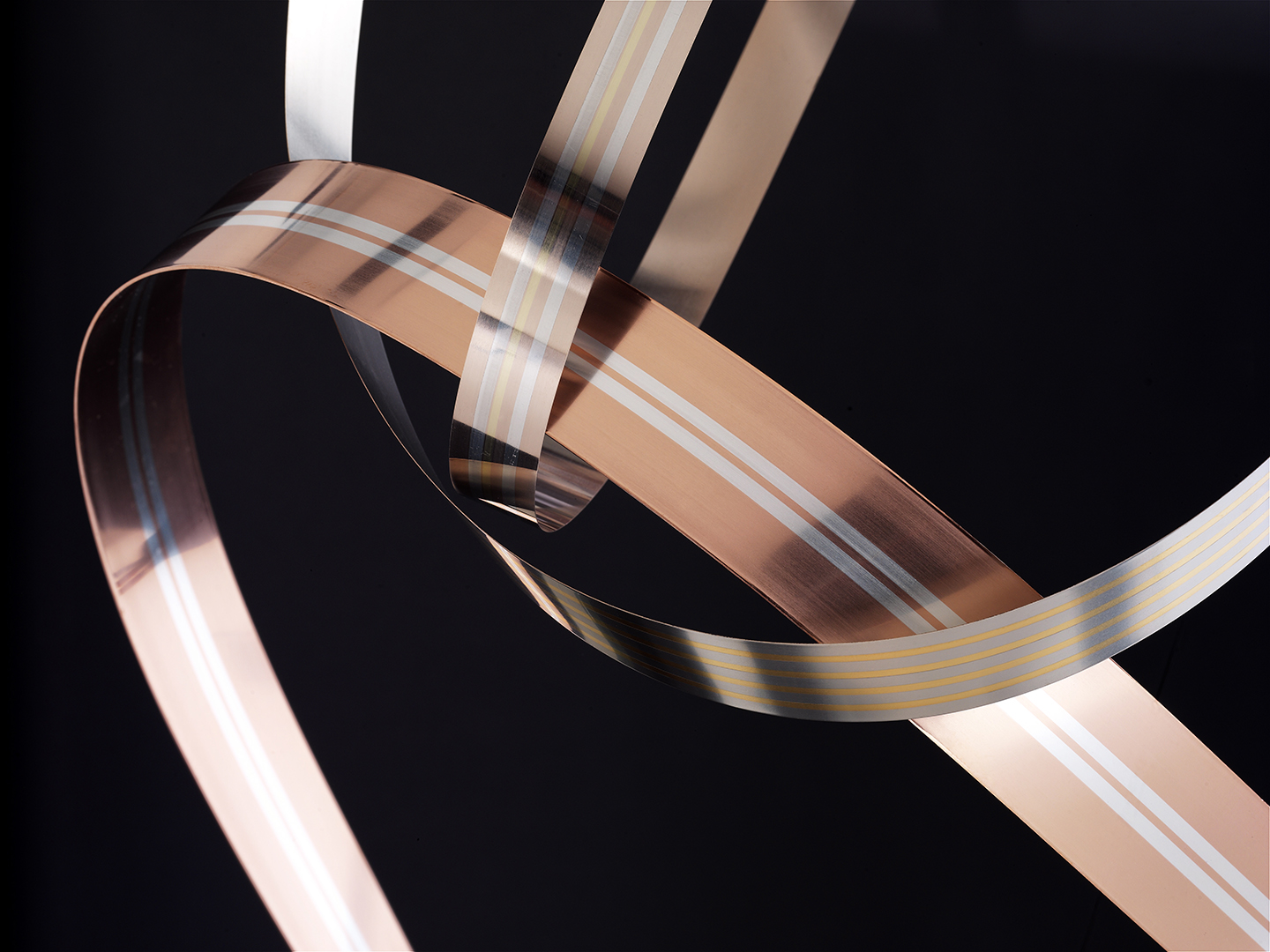

From tiny surface mount resistors used in handheld electronics, to heavy gauge shunts for lithium-ion battery management in electric vehicles (EVs), Materion can design custom resistor materials for a range of applications. Our metal strip resistor materials enable production of components for a broad range of dimensions and ohmic values. These materials promote efficient manufacturing of highly stable and reliable components. They can be provided as coils of easily stamped and formed composite strip.

Materion's welded and clad resistor materials are engineered for your application and can combine many of our hybrid material technologies, including:

• Electron beam bonding

• Inlay or overlay cladding

• Milling profiling

• Electroplating

RESISTOR MATERIAL PROCESSED ACCORDING TO YOUR APPLICATION

We offer several process options for resistor materials, including:

• Electron Beam Welding: We have been a leader in electron beam welding of metal strip since 1974. This high throughput vacuum process securely joins materials side-by-side with narrow fusion zones, which have minimal impact on electrical properties. Welded resistor products are available in gauges as small as 0.05 mm and as thick as 4 mm.

• EquaCast® Process: We process any commercially available resistor alloys, but also offer Materion R270: a copper-manganese-nickel alloy cast with our EquaCast process to provide unparalleled composition control and uniformity for ultimate performance. Download our R270 Resistor Alloy data sheet to learn more.

Benefits

- Superior reliability

- High temperature stability

- Excellent vibration stability

- Long shelf life

Applications

- Electric vehicles

- Handheld electronic devices