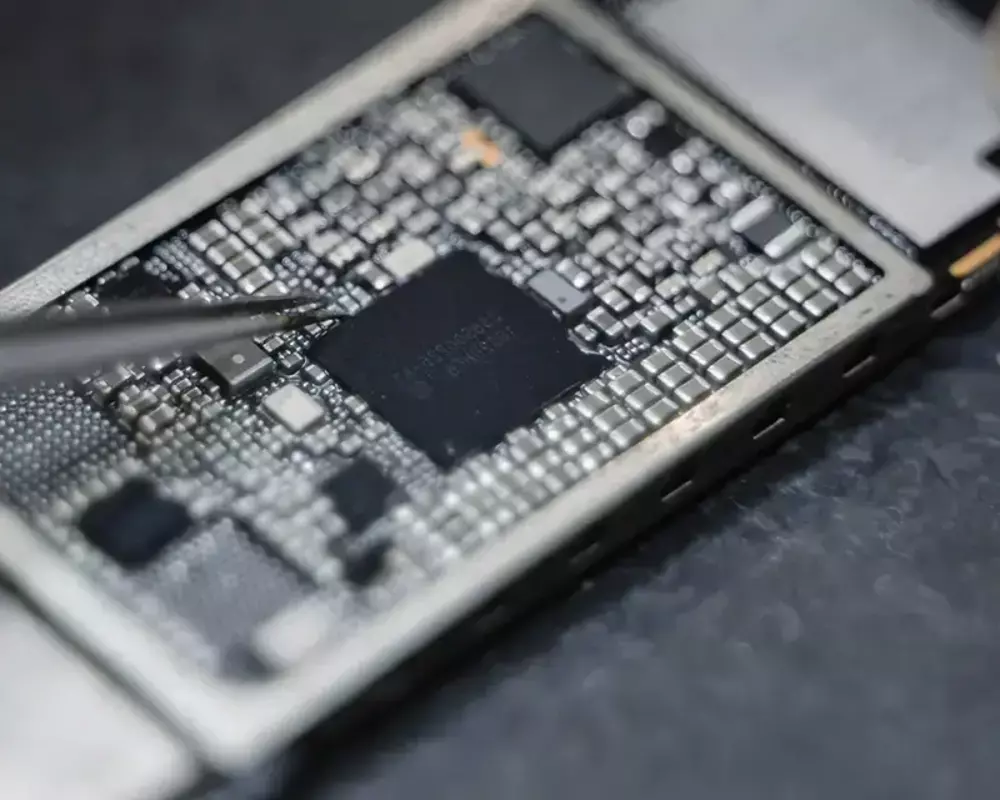

At Materion, we are dedicated to providing advanced materials solutions that enable our customers' technologies and long-term success. We serve a diverse set of markets, including semiconductor, automotive, industrial, energy, aerospace and defense, and consumer electronics.