For decades, Materion has manufactured beryllium metals that are essential for the most advanced technologies in the world, including space structures, military aircraft, defense systems, X-ray and imaging equipment, and more. Beryllium has enabled technological breakthroughs that were previously unattainable. And our team continues to discover innovative uses for this high-performance material.

Beryllium offers an unmatched modulus-to-weight ratio and a low thermal expansion, which makes it resistant to changing shape in extreme temperatures. Other unrivaled end-use advantages include good natural damping, low density, low neutron absorption, a high infrared reflectance and high specific heat.

Beryllium metal is available in rod, bar cut from a block and specialty sizes or shapes.

BERYLLIUM METALS SPECIALIZED FOR UNIQUE APPLICATIONS

We offer beryllium metals in different grades and forms to address the specific challenges of unique, demanding applications.

Instrument Grade Beryllium for Space and Aerospace

Our instrument grades of beryllium metal are ideal for decreasing the weight of instrumentation in aircraft and satellites. They have high micro-yield strength, which allows instrumentation to maintain its form when exposed to stress.

- I-70-H beryllium metal is stable over a range of temperatures -196°C to 226°C /-321°F to 440°F and offers superior reflectivity in the far infrared region without optical coatings. This reflectivity enables designers to create defense applications that are more difficult to detect.

- I-220-H beryllium is used in applications requiring high resistance to plastic deformation at low stress levels which is crucial for telescope supports on space exploration satellites and optical satellites.

Nuclear Grade Beryllium Metal for Reactors

For optimal efficiency, nuclear reactors and fusion walls require materials that perform in high heat conditions and beryllium meets this requirement. Beryllium increases nuclear reactor efficiency, shortens the required storage time after removal from reactors, and reduces hazardous waste production which can help reactors run longer.

Materion beryllium was used to make reflector tiles for the walls in the Joint European Torus (JET), the worlds largest plasma physics experiment focused on nuclear fusion energy production.

Nuclear grade beryllium is also used for neutron reflectors and moderators, neutron filter assemblies, nuclear test reactors and medical isotope reactors.

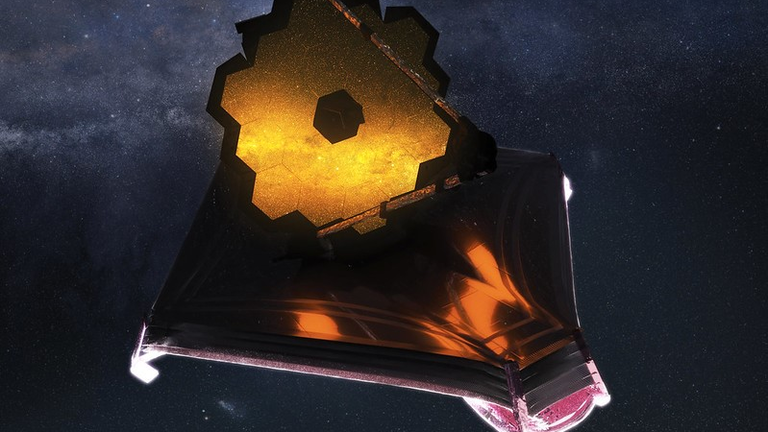

Beryllium Metal for Optical Space Systems

Our beryllium was used to make the mirrors for the James Webb Space Telescope (JWST). Its unique property characteristics, including high thermal isotropy, make it a critical material for optical space applications.

Raw Beryllium Metal

Pure beryllium metal provides high strength, stiffness, low density, heat resistance and reflectivity, making it an ideal material for advanced defense and industrial applications. Materion certifies this metal to conform to a minimum purity of 99.0%.

Structural Beryllium Metal

We produce beryllium metals in a variety of structural grades that provide unparalleled strength-to-weight ratios. These materials allow weight reductions while providing a durable structural material for satellites, reconnaissance systems, semiconductor equipment, aerospace instrumentation panels and electronic-optical targeting systems.

- These materials can be certified to the SAE-AMS7902, SAE-AMS7906, SAE-AMS7908 and SAE-AMS7910 specifications.

SAFE HANDLING OF BERYLLIUM

Beryllium, its alloys, and its salts can be handled safely if certain work codes are observed. No attempt should be made to work with beryllium before becoming familiar with proper safeguards. Read more health and safety information before using beryllium.

Benefits

- Lighter weight & higher thermal conductivity than aluminum

- High stiffness & low density

- Reliable performance in cryogenic environments

- Tolerance in high temperature applications

- High neutron reflectivity & low neutron absorption

Applications

- Aerospace instrumentation panels

- Electronic-optical targeting systems & reconnaissance systems

- Nuclear energy

- Space-based systems, telescopes & satellites

- Semiconductor capital equipment

- Intelligence & surveillance systems