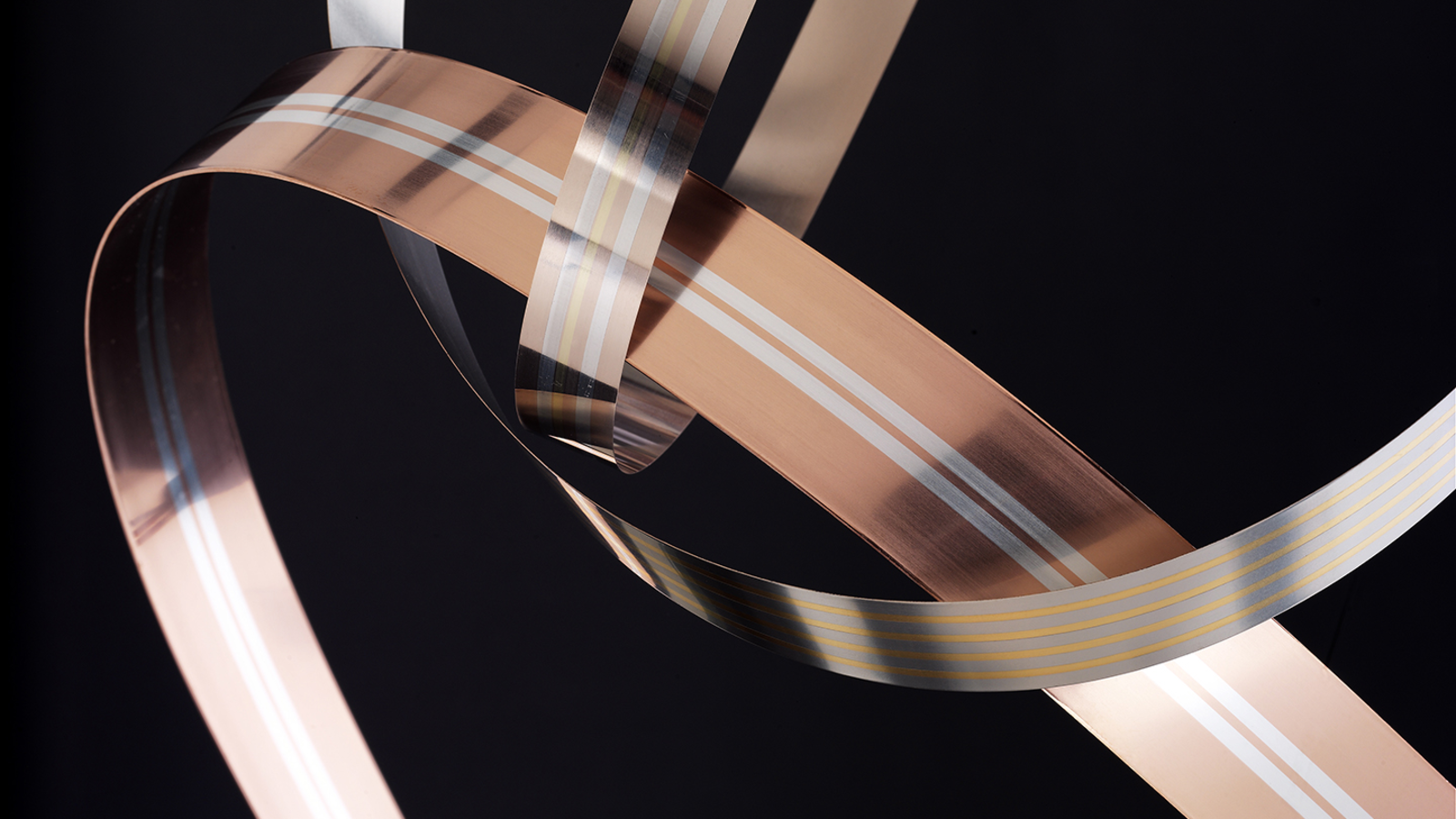

Two or more dissimilar metals can be joined to create unique property sets that deliver superior mechanical, electrical and thermal performance in electric and hybrid vehicle batteries, medical devices, automotive electronics and electrical connectors.

When the properties of one metal do not meet application requirements, cladding is the solution. To access product details and technical information about our most popular clad materials and our customized cladding capabilities, click on the links below:

Components used in automotive electronics, electric vehicle batteries, medical devices and electrical connector applications often require properties that cannot be delivered by just one metal. Materion’s clad products join dissimilar metals, creating and optimizing unique property sets.

Our sophisticated clad metals are engineered to solve tough challenges in automotive design. Materion's clad materials are used in critical safety, fuel efficiency, performance and connectivity applications for the automotive market.