Materion's AlBeMet® and AlBeCast® aluminum-beryllium MMCs offer the benefits of two metals combined into one high-performing material. This unique combination creates property sets that allow for greater design flexibility, specific stiffness and significant performance advantages over titanium, aluminum and conventional aluminum MMCs.

Lightweight AlBeMet and AlBeCast composites meet the demands of advanced technologies and applications in aviation electronics, inspection equipment for semiconductor assembly, optical structures and satellite structures.

ALBEMET COMPOSITE ADVANTAGES

AlBeMet MMCs offer the high modulus and low-density characteristics of beryllium with the fabrication and mechanical property behaviors of aluminum, making them ideal for challenging design applications.

When compared to other metal matrix and organic composites, aluminum-beryllium MMCs are simpler to use and easier to fabricate. AlBeMet composites do not display sensitivity to machining damage, do not require etching after machining and can use typical aluminum coating technologies.

AlBeMet composites can be certified to AMS 7911, AMS 7913 and AMS 7912.

Download the AlBeMet composite technical data sheet.

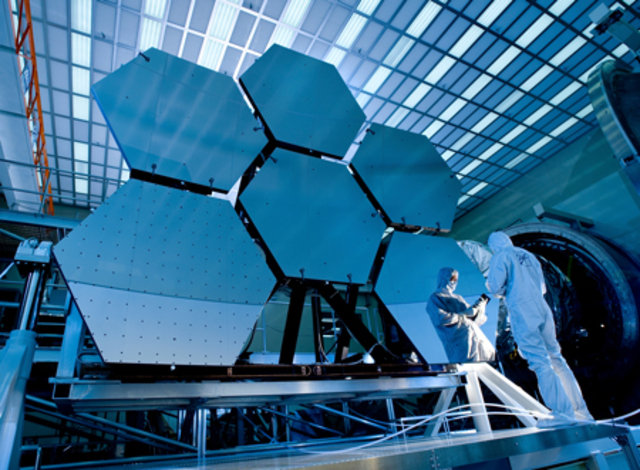

ALBEMET COMPOSITE IN AEROSPACE AND DEFENSE APPLICATIONS

AlBeMet MMCs improve line-of-sight distance and reduce jitter in aerospace and defense optical structures. Its properties allow designers to reduce system size, minimize stress from vibrations and increase the fatigue life of electronic packages while improving performance.

These characteristics, paired with its excellent stiffness-to-weight ratio, have made AlBeMet composites a popular choice in optical and structural components in aircraft, satellite and commercial applications, including the U.S. Military's F-35 Lightning ll, F-16 and the Boeing AH-64 Apache. To date, AlBeMet composites have also been used in more than 150 satellites currently in space.

Download the AlBeMet composite spec sheet for chemistry and physical properties.

ALBECAST INVESTMENT CASTING COMPOSITES OFFER A COST-EFFECTIVE ALUMINUM-BERYLLIUM SOLUTION

Materion offers AlBeCast investment cast aluminum-beryllium composites, which provide many of the same mechanical properties as AlBeMet composites, and can be more cost effective for appropriate applications. Using a near net-shape process requires less material and time for machining. The combination of reduced material and fabrication costs can be significant.

AlBeCast 910 composite is a ternary aluminum-beryllium-nickel composite. The addition of nickel reduces the thermal expansion coefficient, increases tensile properties and improves castability. This makes it a cost-efficient material for housings for avionics electronics or other aerospace applications.

Download the AlBeCast material specification for more information about AlBeCast composites for aerospace applications.

Benefits

- Thermal stability over temperature ranges from -50ºC to 150ºC

- A modulus to density ratio 4x that of aluminum or steel

- Low coefficient of thermal expansion

- 22% less dense than aluminum with 28% higher thermal conductivity

Applications

- Aviation electronics

- Aerospace optical structures

- Satellite structures