Materion has been manufacturing high-strength beryllium oxide (BeO) ceramic materials and BeO powder for decades, and we understand the unique design properties our customers need. These cost-effective advanced ceramics offer a desirable combination of properties not found in other ceramic materials – not even aluminum nitride (AlN). Thermalox® and BW families of advanced BeO (or beryllia) offer superior levels of thermal conductivity and electrical resistivity, along with strength, reliability and weight savings.

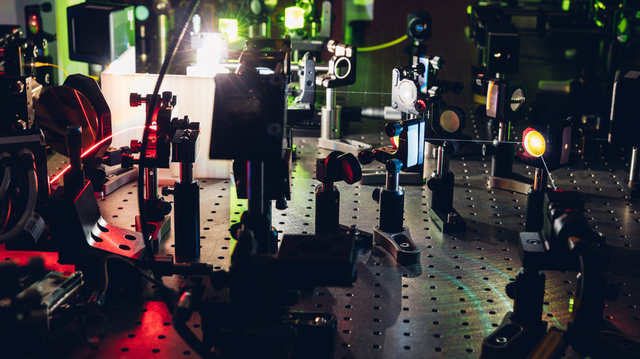

BeO ceramics are ideal for many applications in the medical field, including laser bores in DNA sequencers, heatsinks for defibrillators and components for flow cytometry and hematology. They also excel when used for semiconductor manufacturing, defense applications, energy equipment and components for wireless communications.

BERYLLIUM OXIDE CERAMICS OUTPERFORM COMPETITIVE PRODUCTS

BeO ceramics offer many benefits over competing materials. They can be nine times more thermally conductive than aluminum oxide (Al2O3) ceramic, a commonly used alternative. Additionally, BeO can be up to 80 percent more thermally conductive than aluminum nitride (AlN) and more chemically stable than AlN ceramic in environments containing oxidizing chemicals. BeO ceramics provide the second highest thermal conductivity of all electrically insulating materials, exceeded only by diamonds.

These superior capabilities mean beryllium oxide ceramics excel in applications when product design requirements include:

- Electrical insulation combined with high thermal conductivity

- Miniaturizing the device or enclosure

- Exposing the component to high ambient temperatures

- Airflow or liquid cooling is not possible

- Melting metals at very high temperatures in crucibles

THERMALOX® AND ADVANCED BERYLLIUM OXIDE CERAMICS

Our family of advanced ceramics includes four material grades. Ranging in purity from 99.5% to 99.7%, they deliver improved performance for circuits and high heat applications and have a lower dielectric constant than AlN (6.7 versus 9.7). These materials also offer electrical resistivity and dielectric strength equivalent to competitive materials.

BERYLLIUM OXIDE POWDER FOR THERMALLY CONDUCTIVE COMPONENTS

For some applications, our customers need beryllium oxide in a powder format so that it can be sintered into high-density ceramics. Materion manufactures two grades of beryllium oxide powder which are used to form critical thermally conductive components for high-performance semiconductor applications, microwave devices, vacuum tubes, gas lasers and magnetrons. BeO powder is a highly uniform material that offers high thermal conductivity and great electrical insulation.

We typically supply the powder in -20 mesh, dry condition, which can then be sintered into unique shapes with the properties that meet your exact need.

Using our unique combination of materials forming, firing and fabrication technologies, we can provide you with the highest quality beryllia ceramic materials. Our beryllium oxide ceramics are available dry pressed or iso-pressed, to meet your application specifications.

Benefits

- Superior thermal conductivity & electrical resistivity

- High strength

- Weight savings

Applications

- Aerospace electronics

- Electronics manufacturing

- Laser systems

- Medical equipment