Materion works closely with customers to provide PVD consumables that support the sputtering process and help produce uniform coatings. Our consumables include backing plates, crucible liners, and target bonding epoxies.

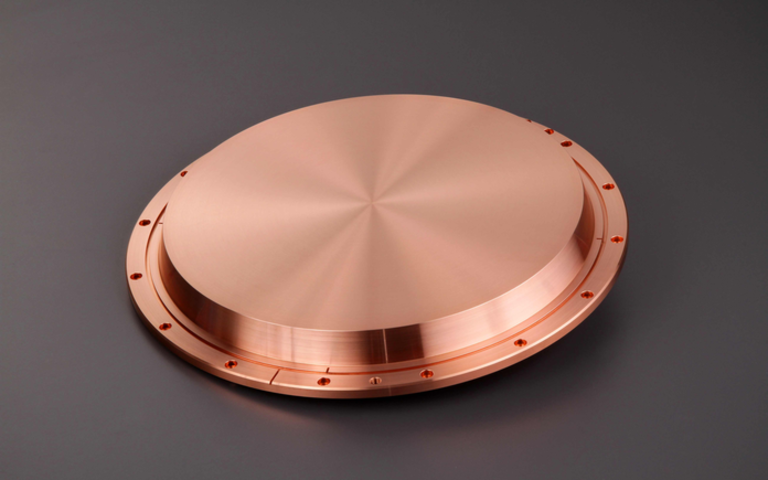

Backing Plates

Available in standard and custom designs to fit a range of targets, our backing plates:

- Are available in various materials, including copper, copper alloys, aluminum and molybdenum

- Adhere well to the target

- Enhance the mechanical strength of the target

- Facilitate the cooling of the target and target assembly

- Permit good heat conduction

When choosing backing plate materials, the physical properties of the target and plate and the expected operating temperatures must be considered. Backing tubes are also available, made of stainless steel or titanium.

Crucible Liners

Materion's crucible liners help improve thermal stability and reduce cycle times for electron beam evaporation processes. Available in a range of materials, our crucible liners enhance performance and are compatible with most manufacturers' evaporation sources. They also:

- Improve thermal stability

- Reduce heat transfer to the crucible

- Initiate higher evaporation rates

- Enable quick material changes to minimize chamber downtime

- Reduce power requirements

- Minimize crucible damage and maintenance

Target Bonding Epoxies

Silvertech PT-1: A two-part conductive silver-filled epoxy that replaces metallic bonding for high-temperature sputtering operations. It creates better bonding for electronic and optoelectronic applications.

| Property |

Value |

|---|---|

|

Volume Resistivity |

Less than 0.001 ohm-cm |

|

Room Temperature Cured |

0.003 ohm-cm @25°C |

|

Heat Cured, ½ hr @ 150O |

0.005 ohm-cm @25°C |

|

Tensile Shear Strength |

1200 psi @25°C |

|

Shelf Life (Sealed Container) |

4-5 mos @ 25°C |

|

Pot Life (After Mixing) |

~1 hr @25°C |

|

Thermal Conductivity |

1.046 x 10-2 w/cm-°C |

|

Operating Temperature Range |

-60°C to 175°C |

Benefits

- Additional target bonding service available for precise target-backing plate alignment

- In-house ISO-17025-certified laboratories allow for comprehensive analytical testing

- Precision parts cleaning and precious metal refining services available

- Industry-renowned technical experts to assist in the development of application-specific solutions

- Full-service precious metal management to help lower total cost of ownership

Applications

- Thin Film Deposition Processes