High-energy deposition processes produce desirable film qualities that provide high transmission, stability to external environmental influences, resistance to laser damage by high-energy lasers, and low stress. These processes rely on the creation of high-energy ions and plasmas to provide the kinetic energy and reactivity necessary to deposit dense film layers. By way of comparison of process energies, the energy provided by resistance-heated evaporation is a few 10ths eV. High substrate temperature ~300 ⁰C is required with resistance-heated evaporation to supply kinetic energy to mobilize the arriving adatoms and produce moderately dense microstructures. When augmented by simultaneous heavy-ion bombardment (Ar+) with energies of ~50-70 eV in the process called Ion Assisted Deposition (IAD), the thermal films can be compacted to an amorphous microstructure of higher densities. More complete oxidation also results in the process in which reactive oxygen ions are also produced. The results are films that meet the already mentioned favored qualities to varying degrees.

However, regarding properties such as internal stress, optical absorption and environmental stability, the process leaves much to be desired. More energetic processes, such as magnetron sputtering with energies is in the range ~10 eV, produce repeatable high quality films with low stress. Depending on the process parameters associated with the variety of techniques, other preferred properties may vary in quality. The user must adapt process parameters to fit the materials and application.

Ion beam sputtering (IBS) was developed to enhance these properties: environmental stability, laser damage threshold and optical absorption. IBS today produces the highest quality oxide-compound films. In the process, ions of energy ~1kV from a Kauffman-type ion source sputter material from a target, and the high-energy Ar+ and O2 ions bombard the growing film. IBS is regarded as a reactive process from a metal, alloy or even a full oxide target. The high energies present result in stoichiometric amorphous films with near bulk density, low scatter, and near zero absorption at lower substrate temperatures. Applications requiring the minimum absorption, such as ring laser gyroscopes and high-energy laser coatings, benefit the most from IBS. The high packing density of the films ensures that the spectral properties of IBS coatings are invariant between humid and arid environments. Currently, metal oxides dominate IBS since the reactive gas is well understood and is also non-hazardous and transparent in the critical UV, VIS and NIR ranges. Fluorides, Nitrides and Carbides can be created, but the reactive gases or the mechanical stability of the target, can pose significant challenges.

One aspect of high packing density that can become an issue is the high stress that is built into thick coatings by the high compaction energy of the impacting ions. Measures are implemented to minimize this potential problem by adjusting deposition parameters. Large areas can be uniformly coated by IBS, but stress limits the number of thick layers possible. While the substrate temperatures can be lower than IAD with electron beam processing (eBeam), the targets themselves are subject to much higher heat flux as a function of incident sputtering Ion Beam angle, intensity and interference.

The higher target temperature is not completely negated by advanced target cooling approaches such as rolling and annealing. Greater detail will follow concerning the risks associated with forged microstructural variations in metal targets or fragile brittle metals and the limitations of pressed compounds.

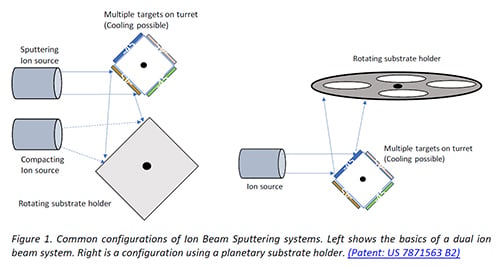

Figure 1 shows two basic arrangements of a single beam IBS. On the left, the substrates and targets are mounted on their respective turrets to permit multiple materials to be sputtered by selecting target material; also, to improve thickness uniformity by rotating the substrates in the sputtered beam. A second ion source bombards the growing film to increase packing density.

The right-hand figure shows the configuration that uses a planetary rotation for coating larger substrates or many smaller ones. The targets and target assemblies can be cooled using a rotating feedthrough in the chamber wall and/or water-cooled backing plates. Not included in the figures are the all-important gas inlets, the optical and crystal thickness rates and thickness monitoring accessories.