Stress relaxation is a thermomechanical phenomenon where elastic strain is slowly converted to plastic strain, even at stress levels far below the yield strength. Because contact force is generated only by the elastic strain and not by plastic strain, stress relaxation results in a continual decay in contact force. This slowly increases the resistance of the contact interface, leading to its degradation, loss of signal integrity and reduced reliability.

Contacts can relax anywhere there is heat, such as underneath the hood of a car, near a jet engine, in downhole oil & gas drilling operations, and other such environments. Without careful selection of your materials, these locations can provide everything needed for stress relaxation.

Stress relaxation can:

In order to have good electrical contact between the two halves of a contact interface, there needs to be sufficient contact force holding the two surfaces together. The minimum required contact force is a function of the shape of the surfaces in contact, as well as the type and thickness of the plating or other coating on the surface. This is typically accomplished when a pin of some sort deflects a socket. This deflection (strain) of the socket generates stress, which creates the contact force.

If the stress in the deflected socket contact is less than the elastic limit of its base material, then all the strain is fully elastic and is entirely recoverable when the load is removed. When the pin is taken out of the socket, the socket will return to its original shape.

However, if the strain is greater than the maximum possible amount of elastic strain, at that point the stress exceeds the yield strength. The additional strain will be plastic strain, which will not recover when the load is removed and results in permanent deformation of the socket.

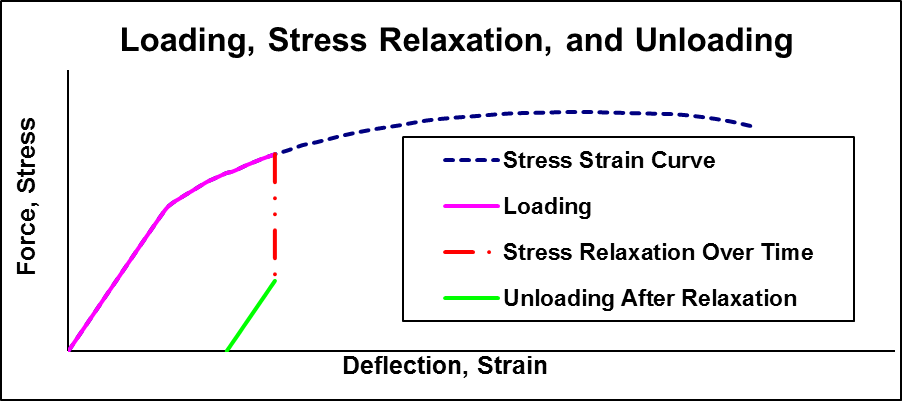

Figure 1.Schematic of What Happens During Stress Relaxation

In the chart above, the dashed blue line indicates a material’s stress-strain curve, which parallels the force-deflection curve of a socket made from the same material. As the pin is inserted, the stress in the socket and the normal force generated increase along the pink line. As the mated connector is exposed to heat, the stress and force continue to drop along the red line. When the pin is removed, the curves unload along the green line, parallel to the original loading curve. This slope is equal to the elastic modulus on the stress-strain curve, and the spring rate on the force/deflection curve. The total amount of plastic strain or permanent deformation when the load is removed is the distance between the origin and the end of the green line.

The amount of stress relaxation is a function of time, temperature and initial stress level (both applied stress and residual stress). The alloy and temper used, as well as the material orientation, also play a role. Different materials will show differing amounts of stress relaxation under the same circumstances. Alloys that are heat treated to their final strength level typically have better stress relaxation resistance than those that are strengthened only by cold work.

Greater resistance to stress relaxation implies:

For alloys that are not heat treated prior to use, a stress relief heat treatment may improve the stress relaxation resistance, although not to the degree that you would get in a fully heat-treated alloy. Materials that are age hardened after forming have greater stress relaxation resistance than those that are heat treated first and then formed. Within a given alloy system, different tempers will also have different susceptibilities to stress relaxation, depending on the amount of cold work and heat treatment applied. Also, materials and tempers that are highly anisotropic (directional) in nature may relax differently depending on how the parts are oriented. It is crucial to understand which way parts will be laid out when stamping them.

In order to prevent the decay of contact force over time due to stress relaxation, the initial design normal force must be increased to allow for adequate force at end of life. The normal force must be increased by an amount equal to the expected loss in contact force over the desired lifetime of the connector. Higher initial normal force means additional plating wear and increased connector mating force. Early plating wear can lead to reduced reliability. Increased connector mating force could become a problem for mating connectors with many contacts because ergonomic regulations specify a maximum permissible mating force (usually 75 N in North American automotive applications).

Materials with better stress relaxation resistance will require less initial design normal force and can reliably operate at higher temperatures than those that relax easily. Stress relaxation resistance cannot be inferred from basic material properties – it is a fundamental material property which must be tested separately.

Thanks for joining me for another edition of In Our Element. For ongoing industry updates, connect with us on LinkedIn.