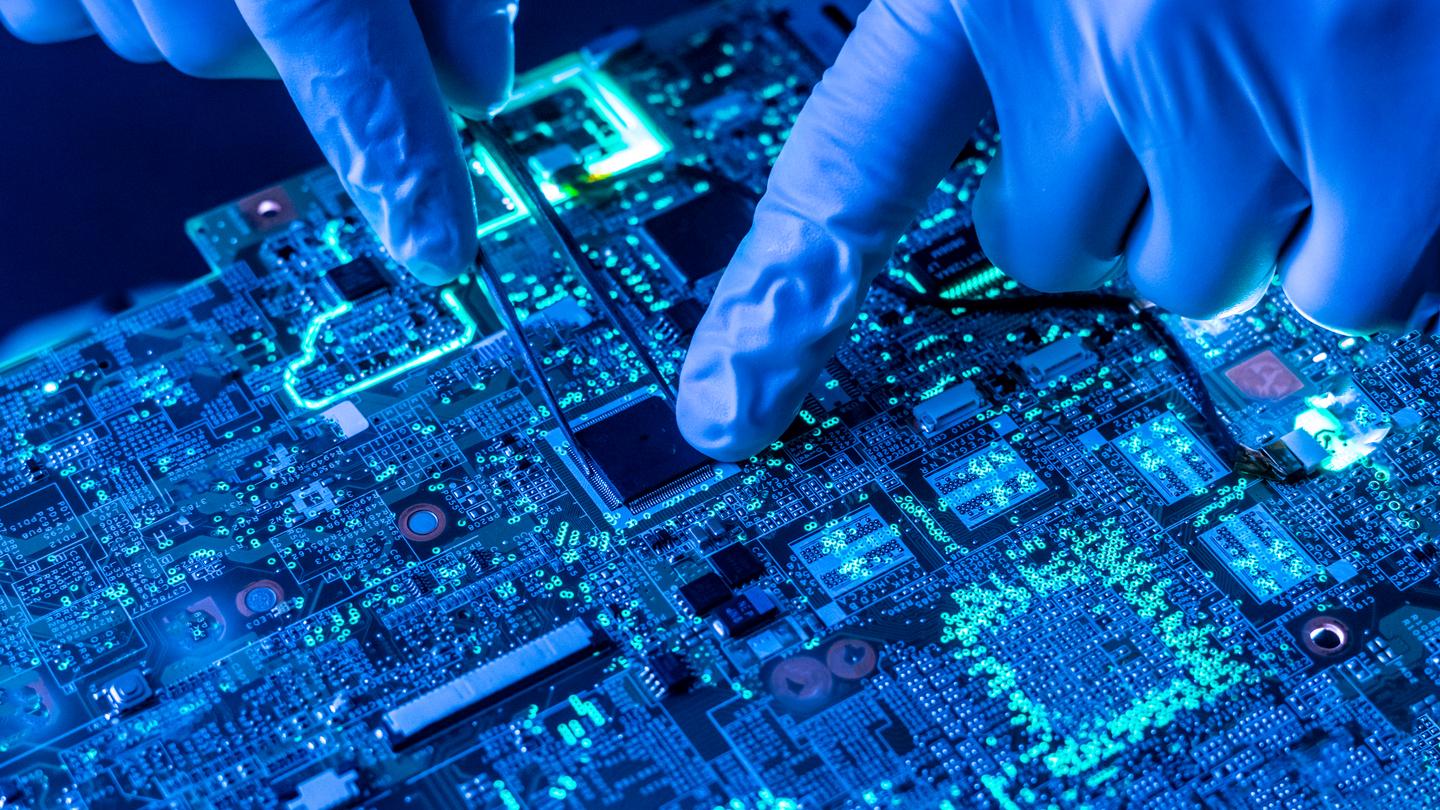

We combine industry-leading technology and service to deliver optimal package performance for ultimate hermeticity, quality and reliability – all critical requirements for the successful operation of any electronic device. Our solder assembly services include package design, prototypes, testing and mass production. Working closely with our customers, we create new material solutions, providing value to our customers by offering:

- Turnkey soldering and assembly services

- Guidance on design and manufacturing considerations

- Custom microelectronic and optoelectronic packaging for hermetic applications

With a qualified team and a passion for providing customers with unmatched products, services and support, we offer specialized services to help you stay ahead of the latest market and technology trends.