Friction is a highly variable quantity with a virtually unlimited number of factors influencing it. So, a common question in regard to friction is, “What value for coefficient of friction should I use in my calculations?”

Luckily, the world is filled with test data. There are entire laboratories dedicated to testing friction and wear behavior. The problem is again that the data are truly valid only for the specific system under test. So, what value should you use in your calculations?

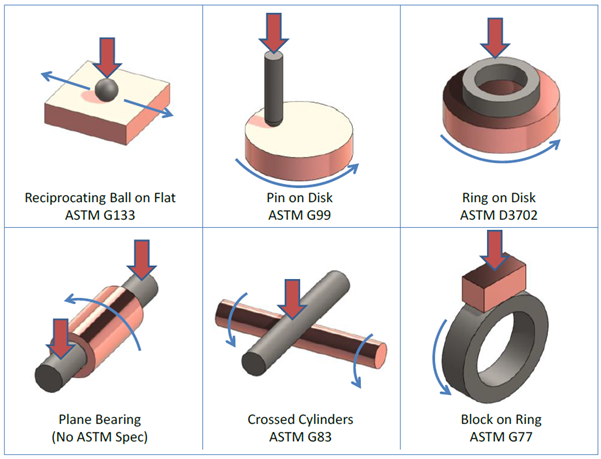

Figure 1. Greatly Simplified Schematics of Various Friction and Wear Test Methods

In Figure 1 above, one part of each test couple is held stationary while the other moves. In some cases, the wear test specimen (copper color) is the stationary part, in other cases it is the load applicator (steel color). Motion is represented by the blue arrows; applied load by the red arrows. For clarity, no support apparatus, friction sensors or load cells are shown.

The first thing to do is find a system that approximates yours. Some examples of standard friction and wear test set-ups are shown in Figure 1 above. The surfaces may be flat on flat, flat on convex, convex on convex, or concave on convex. The relative motion may be linear or rotary. The materials used for the two surfaces should be the same as those in your application, with similar relative size, surface finish, and hardness. The load should be of a similar magnitude, and the lubrication conditions should be similar. Sophisticated test equipment will measure the coefficient of static friction (μS) at startup and will monitor how the coefficient of kinetic friction (μK) changes over time.

Even under constant load and constant motion, the friction coefficient will change over time as the test samples wear and as lubrication runs out and gets replenished. The roughness of the surfaces will also change over time. For these tests, the usual pattern will be an initial upward spike in friction, followed by a decrease as the surfaces wear in (effectively polishing each other), then a gradual increase as wear debris starts building up in the interface, increasing wear and friction between the surfaces.

In fact, as you may have guessed, the primary purpose of the tests shown above is to measure the wear behavior of the various material couples. A number of the configurations represent bushing and bearing applications rather nicely. Frictional behavior is just a fringe benefit of these tests. Some electrical connector manufacturers have done their own testing to compare the frictional behavior of various coatings. While much of it is proprietary, some general trends have been published.

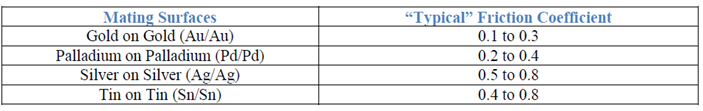

For electrical and electronic connectors, the coefficient of friction will be governed by the geometry of the pin and socket (whether curved or flat surfaces), the normal force, the presence or absence of lubricant, the type of lubricant, wipe length, and the composition and hardness of the plating, underplating, and base metal. (Learn more about how our advanced materials enable better performance in electronic devices.) Some generally reasonable values for friction coefficient are shown in Table 1, based on the top layer of plating.

Table 1. Approximate Typical Friction Coefficients for Electronic Connector Surface Finishes

The numbers in Table 1 assume that the mating surfaces are identical and that there is a nickel underplate for increased resistance to wear and corrosion. Harder, smoother, well lubricated surfaces with lower normal force will typically have lower friction coefficients than softer, rougher, unlubricated surfaces with higher normal force.

Friction becomes important when calculating connector mating and removal forces, or when running general finite element simulations of contact mating. The two approaches to use would be to assume a friction coefficient based on typical data, and explicitly state that assumption. The second approach would be to run the analysis with multiple values of coefficient of friction, and to report the results for all cases used. The latter results would be good for ensuring that the proper plating and lubricants are specified for the design.