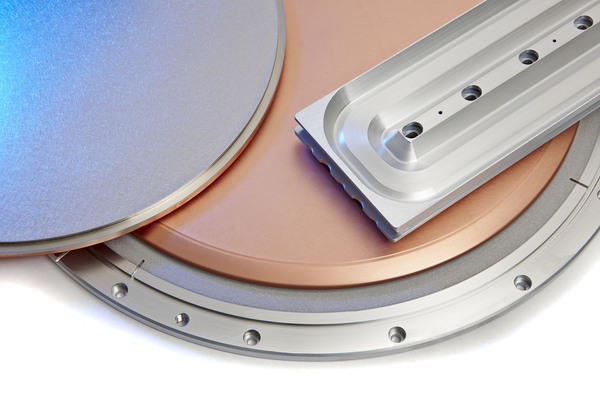

Materion produces high-purity tantalum target plates, critical for microchip architecture in the growing semiconductor industry. These plates sputter microscopic thin layers of tantalum onto silicon wafers. This enabes next-gen logic chips like DRAM and 3D-NAND with advanced nodes and superior performance.

LEADING PROPERTIES OPTIMIZE YOUR PVD PROCESS

We have decades of expertise in high-volume production of texture-controlled tantalum for sputtering targets. The result? Disks manufactured with exceptionally consistent properties. End-users benefit from:

- Chemistry control to parts per billion

- High-quality deposited films (uniform thickness, resistivity)

- Customized deposition rates for optimal sputtering performance

Materion's reliable, consistent, and proven methods have allowed us to remain a leading US-based manufacturer. We supply tens of thousands of advanced texture-controlled plates to the semiconductor industry for consistent and rate-controlled deposition.

TANTALUM MATERIALS

We are a global leader in tantalum materials. We offer >99.995% purity with chemical and metallurgical uniformity for optimal performance in logic, memory, RF & power devices, and hard disk drives. Our tantalum is available in a variety of forms, including advanced texture-controlled plates, sputtering targets, coils, and pots.

In addition to industry-leading materials, our R&D scientists and engineers partner with customers to develop custom solutions to solve unique needs and challenges. We also offer our customers access to world-class, in-house laboratories and the most comprehensive analytical testing available.

Benefits

- Decades of expertise in high-volume production of texture-controlled tantalum for sputtering targets

- Specialized facilities optimally designed for the products we manufacture

- Industry-renowned technical experts to assist customers in developing application-specific solutions

- In-house ISO-17025 certified laboratories provide customers with comprehensive analytical testing

- Conformant tantalum products (RMAP certification)

Applications

- DRAM

- 3D-NAND Memory