Engineering thin-film coatings to withstand abrasive and impact forces involves complex physics and chemistry problem solving. Hardness, internal and external bond strengths, and surface abrasive wear resistance, are physical properties determined by materials and deposition processes. An additional parameter is the relationship of the surface chemistries of the multi-layer interfaces and layer thicknesses.

Coating of polymer surfaces poses special considerations imposed by temperature limitations and compositional, thermal expansion coefficient, and hardness differences compared with coating materials and deposition processes. We begin the discussion with a model that illustrates the construction and composition of a multi-layer coating designed for durability.

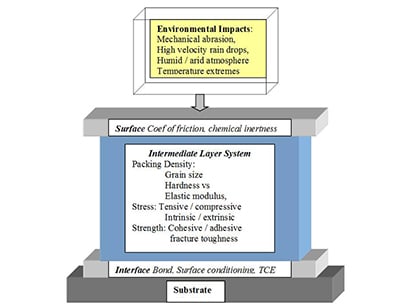

The model presented in Figure 1 illustrates the multiple and inter-related components that influence and determine the hardness, strength, and wear properties of mechanically durable thin films. The model applies to any substrate material. Later we apply it to polymer surfaces.

Figure 1. The functional locations of important mechno-chemical interfaces that produce mechanically durable coatings.

Engineering a mechanically hard and durable coating begins at the substrate surface and involves the phenomena of nucleation and the characteristics of the film’s nanostructure that promotes dense adherent growth. Nucleation density, and the establishment of interfacial bond strength, are functions of substrate surface energy. The kinetic and chemical energies of the arriving adatoms influence mobility on the surface and the initiation of surface bonds. High surface kinetic energy promotes 2-D coverage of the surface in advance of 3-D growth, thereby insuring a dense compact nanostructure as opposed to columnar growth with its characteristic large void volume.

Often a surface conditioning layer must be added to prepare the surface for chemical bonding, as discussed above for polymer compositions. When applying coatings to materials of dissimilar chemistry, specific metal oxides can be applied in thin layers to the substrate to form a chemically reactive interface bond. Specific fluoride compounds or mixtures are required to promote strong interface bonds on Infrared (IR) substrate materials such as Ge, ZnSe and ZnS. Another consideration that interferes with strong physio-chemical bonding is contamination. This must be removed prior to coating deposition…