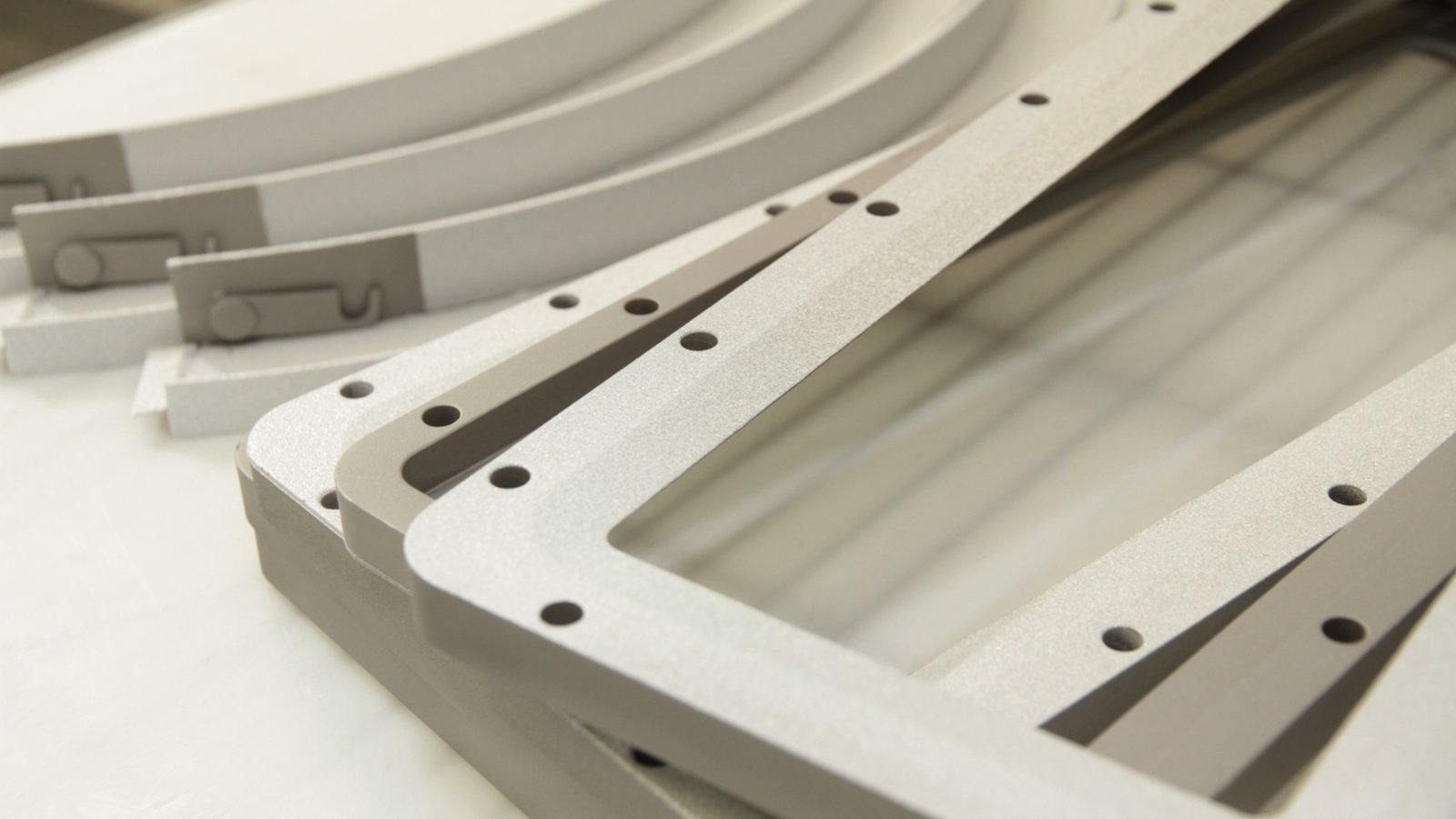

While it plays an integral part in semiconductor manufacturing, physical vapor deposition (PVD) tends to be a highly inefficient process. Less than 10% of deposition material ends up on the intended substrate, leaving more than 90% on surrounding shielding. By carefully removing and recovering this material, manufacturers can realize significant financial and operational benefits.

In the case of gold, for example, even a small 1% improvement in recovery yield at today’s prices could save more than $700 per kilogram of gold evaporated. At scale, these savings can easily run into tens of thousands of dollars, especially when working with an experienced shield/parts cleaner like Materion, which annually recovers more than 65,000 troy ounces of gold for its customers.

There are two main approaches to PVD shield cleaning: physical methods (such as scraping or bead blasting) and chemical methods.

Physical cleaning has its advantages, including the fact that it does not require a high level of expertise or specialized equipment to implement. The downside of physical cleaning, however, is that it presents a much higher risk of shield damage and shorter shield lifespans.

Chemical cleaning, on the other hand, offers better overall throughput and maximum cleanliness, and lends itself to easier installation of returned shield kits at preventive maintenance. It requires a high degree of technical expertise to maximize precious metal recovery and balance the selection of under- and over-aggressive chemicals.

Careful consideration must also be given to the specific chemistry appropriate to a particular film and shield substrate, as well as for the optimum reclaim process to provide maximum refine yield. Materion’s engineers have formulated chemical “recipes” designed for a range of deposition film stacks. These include gold, silver, platinum, palladium, iridium, rhodium and ruthenium.

There are at least three things to consider when it comes to limiting particulation and poor film adhesion:

For enhanced applications or challenging particle-generating films, AI Twin Wire Arc Spray, or TWAS, is the method of choice. This approach to texturing can help improve performance by limiting the number of particles generated. Lower levels of particle generation translate into longer tool uptime, fewer device failures and extension of the preventative maintenance schedule.

Materion also ensures optimum vacuum pump downtime for cleaned and returned shield kits by removing residual water using drying and bake-out processing. Proper selection of shield kit packing materials compatible with clean room and ultra-high-vacuum environments prevents outgassing contamination.

Materion has the experience and bandwidth needed to work with customers based on their unique business and financial goals, cash flow situation and settlement needs. If, for example, metal price insulation is important, metal (or “pool”) accounts allow customers to apply recovered precious metal against a future deposition material purchase. In many cases, the net effect of such accounts is a reduction in the overall value of purchase orders, which in turn could facilitate quicker and easier approvals for those working in purchasing functions.

Outsourcing shield kit or precision parts cleaning to a specialty firm such as Materion carries the additional benefit of releasing valuable engineering and technical resources to core fab activities. Physical footprint within the fab devoted to cleaning processes – including the clean room – can instead be freed up for product manufacturing.

For more information visit our shield kit and precision parts cleaning services page.