With our expertise in advanced materials, microelectronic packaging, and solder lids for hermetic packaging, we deliver total protective solutions for your product.

Our product line encompasses a wide range of cover lids for hermetic packaging that meet the demand for very low thermal resistance and radio frequency loss in RF and microwave packages.

Need help in selecting the right microelectronic packaging for your application? Review our Microlectronics Packaging brochure for expert guidance and technical details.

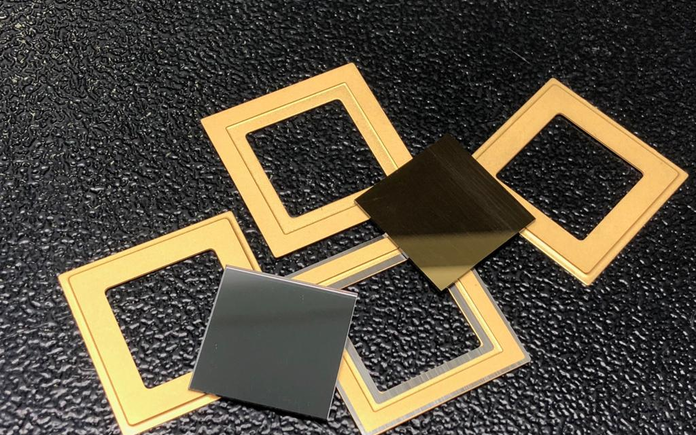

SOLDER LIDS WITH WINDOWS

Materion developed its unique Visi-Lid™ covers for customers who require a solder packaging lid with a window attachment for their photonic package. A wide array of advanced technologies utilize solder lids that require transmittance of electromagnetic radiation. We have your custom solution.

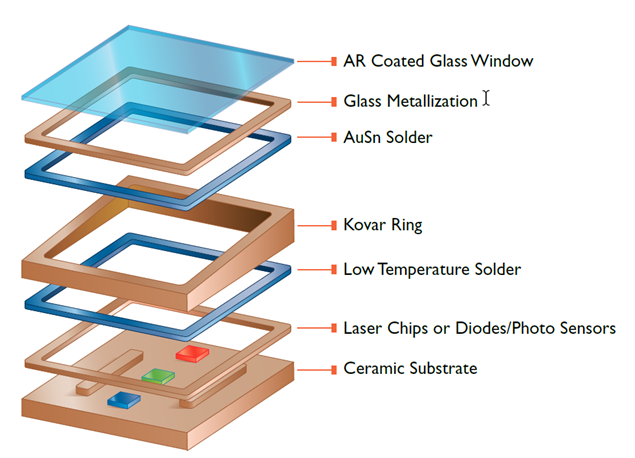

ANTI-REFLECTIVE (AR) COATINGS FOR LIGHT-SENSITIVE ELECTRONICS

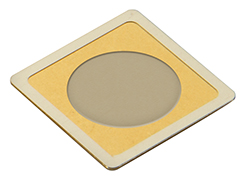

For more economical packaging lids, a solder frame can be tack welded directly onto the metallized window using Materion's Visi-Cap™ products.

(Note that Visi-Caps do not have a Kovar® frame.)

Visi-Cap Assembly Diagram

ACHIEVING IDEAL SOLDER LID TRANSMITTANCE

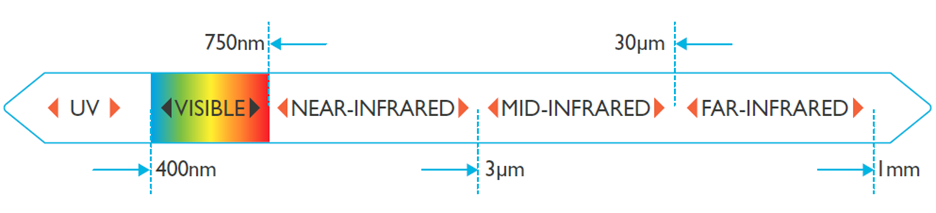

An optical assembly passes light at specified wavelengths. Obtaining the desired level of transmittance for the package window depends on selecting the right combination of quality material, surface finish, and anti-reflective coating.

Visi-Lid Wavelength Diagram

These assemblies can hermetically seal various device packages. A simple Visi-Cap cover assembly consists of an AR-coated and metallized window tack welded with a solder frame onto a metallized area of the window. More complex Visi-Lid cover assemblies feature a metallized window sealed onto a plated Kovar frame.

PATENTED COVER LID FOR MICROELECTRONIC PACKAGING

Materion' s patented Combo-Lid™ covers deliver superior sealing to protect high-reliability applications in semiconductor, MEMS (Micro-Electro-Mechanical systems), crystal oscillator, medical, and optical devices from moisture and particulates. We specialize in fail-safe electrical housing lids that perform in extremely harsh environments.

LOW-TEMPERATURE LID SEALING

While it is critical that semiconductor packages have a reliable hermetic cover to protect sensitive electrical components, some chips will not tolerate high temperatures during soldering. Therefore, a low-temperature seam sealing process is required. Materion offers an innovative Etch Lid™ cover for hermetic applications in which semiconductor chips are unable to withstand solder reflow temperatures inside an oven.

PERSONALIZED ASSISTANCE FOR LID & FRAME COMPOSITION

We build a deep understanding of the technical challenges our customers are trying to solve. Materion engineers can offer guidance for customized hermetic cover lid designs and dimensions, frame composition, tolerances, and related tooling.

Benefits

- In-house engineering support from initial design through final assembly

- Extensive tooling library of solder preforms and cover lids available

- Precious metal alloys to accompany your solder applications

- Support for most configurations, applications, and volume requirements

- Convenient global operations in North America, Singapore, and the Philippines

Applications

- Semiconductor

- MEMS

- LIDAR

- CCD chips

- Medical Equipment

- Photodiodes

- Laser Diodes

- Sensors