After nearly 20 years in development, the successful launch of the James Webb Space Telescope was an extraordinary achievement that promises to deliver new insights into the creation of the universe and the evolution of our solar system. We take great pride in the role that Materion played in taking this telescope from concept to reality.

Materion is focused on innovating advanced materials that enable next-generation technologies. Whether we supplied beryllium metal, metal matrix composites, specialty alloys, or high purity metals, our materials have helped advance space programs since the beginning. And as we innovate the materials that will enable the next ground-breaking project, it’s the perfect time to celebrate Webb and the space programs that came before it.

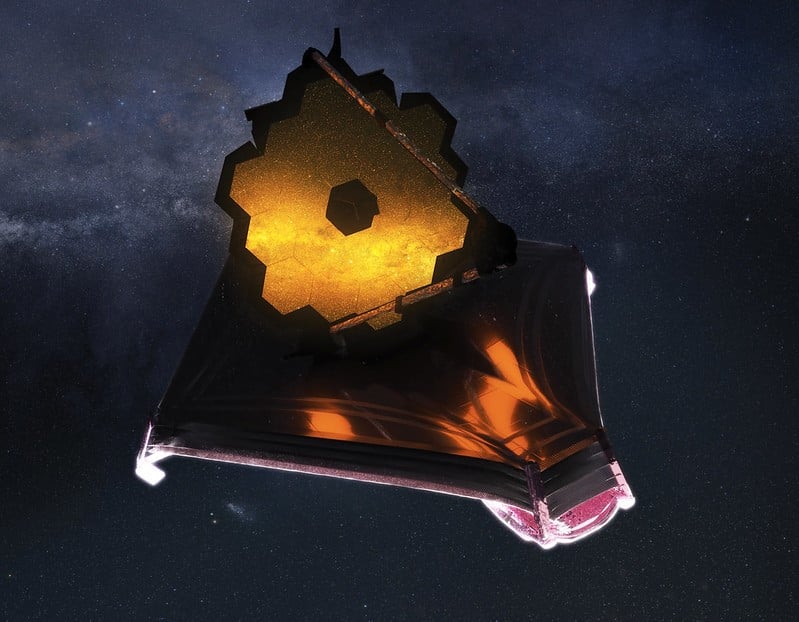

The Webb is the largest and most powerful space telescope ever constructed. Its enormous size and the frigid temperature required for its operation presented extraordinary engineering challenges. Working with NASA nearly 20 years ago, Materion engineered a special grade of gas atomized beryllium which is lightweight and has the properties needed for the telescope’s primary mirror. Eighteen gold-covered beryllium mirror segments will enable scientists to see farther in the universe than ever before – with nearly 100 times more power than the Hubble telescope.

James Webb Telescope | Photo: NASA/ Telescope ih position and fully deployed

When the telescope reaches its destination about one million miles away from Earth, it will undergo six months of commissioning in space—unfolding its mirrors, sunshield, and other smaller systems; cooling down; aligning; and calibrating to be able to conduct scientific observations. Once fully deployed, Webb will send images of galaxies more than 13 billion light years away back to Earth.

In addition to the primary mirror, Materion materials are included in the telescope’s secondary and tertiary mirrors. While the mirrors are clearly the main showpiece, Materion also supplied highly engineered metals to help manufacture the energy-producing solar panels on the Webb that helps power the system by converting sunlight into electrical energy.

Materion also developed new bands for the NIRCam instrument, filters for the Near Infrared Imager and Slitless Spectrograph, and NIRCam coronographic occulting masks that block out things that do not need to be seen. At the time of development, the technology was new and very advanced, extremely challenging and engineering intensive.

Materion provided 18 hexagonal beryllium mirrors for the JWST. | Photo: NASA

In addition to working with beryllium metal, NASA has used Materion’s beryllium oxide (BeO) technical ceramics for more than 50 years, and in 2017 the organization selected Materion to supply BeO components for its Kilopower fission reactor project.

The Kilopower project is focused on developing affordable fission reactors that could someday deploy power production for future planetary missions and enable long-term human stays on the moon or Mars. While initial testing has been successfully completed, the project is in development.

When the NASA was established in 1958, the agency had its sights set on the first American human spaceflight, also known as Project Mercury. Sending a human into space ushered in a new challenge that had to be solved prior to launch—the need for a return capsule that could withstand the heat of reentry.

NASA studied beryllium as a heat shield and worked with Materion (then known as the Brush Beryllium Company) to make “technological history” by forging 80-inch diameter billets of Quantum Mechanical Vacuum (QMV) beryllium for the heat shield on the back of the capsule. The project was a success and just as the space race was heating up, the first American, Alan Shepard, traveled to space for a 15-minute suborbital flight.

As noted in this 1959 advertisement, Materion (formerly Brush Beryllium Company) developed beryllium materials that aided in the first U.S. human spaceflight.

Project Mercury consisted of five additional flights, four of which orbited the Earth. These critical missions proved that humans could survive in space and paved the way for the next groundbreaking mission.

The next stage in expanding the space program came when NASA launched Project Gemini in 1966. Following the success of the beryllium heat shields used on the Mercury capsules, beryllium produced by Materion was made into shingles to protect the parachute enclosure of the Gemini capsules.

Time lapse of the Gemini X launch | Photo: NASA

This successful two-man mission proved that astronauts could remain in space for an extended period of time (at least two weeks) and conduct work outside of the shuttle. It was these critical achievements that enabled the impending Apollo 11 mission to the moon just three years later—a mission that took place exactly fifty years ago and paved the way for decades of exploration to come.

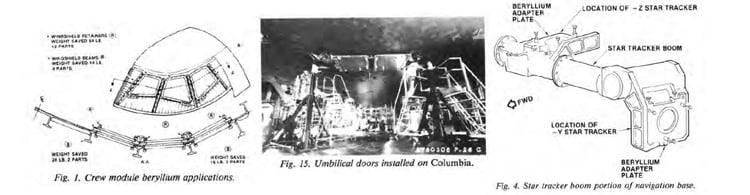

After the successful Apollo missions to the moon, NASA shifted its focus during the 1970s to the Space Transportation System (STS)—better known as the Space Shuttle Program, which was comprised of five different shuttles that embarked on 135 missions over the course of 30 years.

NASA had seen the proven success of beryllium metal and beryllium-oxide ceramics (BeO) on previous missions, so Materion was selected to create several key components for all five of the shuttles to withstand both the high heat reentry of the shuttle and the extreme cold of outer space.

Beryllium served as a critical material in the creation of components like the shuttle window and door frames and the navigation system on the Space Shuttle.

From constructing the International Space Station to taking beryllium materials into space that aided in the repair of the Hubble Telescope, the Space Shuttle Program enabled incredible research and progress over the three decades that lead to technological advancements for NASA and ushered in a new era of exploration.

On the heels of many successful expeditions, two rovers named Spirit and Opportunity set out to explore the dunes of Mars in 2004. Materion’s AlBeMet® material was used to make more than 350 structural fittings on both rovers, helping to enable their successful landing and deployments on Mars.

Materion’s Delta, Utah beryllium mine (top) and the Mars Rover (bottom - photo by NASA).

Both Spirit and Opportunity far exceeded their life expectancy and collected imagery and data that have provided a look into the makeup of the mysterious planet—including evidence of previous wet conditions that may have supported microbial life. Scientists have since been able to utilize the collected data to paint a better picture of the planet’s history and lay the foundation for future Mars exploration.

Just as each space mission builds on knowledge gained from its predecessors, we are proud to continue building on our legacy in space and to provide materials solutions that ensure future missions achieve goals that once seemed out of reach.