There are many factors to consider when choosing the right material for an application or product: strength, flexibility, processing, cost, availability - the list goes on. In this post, we discuss the factor of material formability to tell you how to determine it and why it’s important.

The formability of a copper alloy strip material is usually measured by the R/t ratio (sometimes called the MBR/t ratio). This specifies the minimum recommended inside radius of curvature (R) that is necessary to form a 90˚ bend in a strip of thickness (t) without failure. Materials with good formability will have small R/t ratios, whereas less formable materials will have higher R/t ratios. If the R/t ratio is equal to zero, then the material will, theoretically, survive a sharp (zero radius) bend. For a 90˚ bend, this means that the two legs of the punch will meet at perfect right angles.

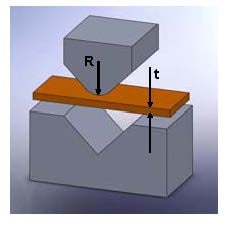

Several methods are used to calculate the R/t ratio for a given strip material, including V-block and W- block in guided, semi-guided, or unguided tests. In the V-block test, 90˚ punches with various radii of curvature are used to force a test piece of strip into a 90˚ die (Figure 1). After each test, the test piece is removed and the outer radius of the bend is inspected for cracks. If there are visible cracks, the material has failed the test. If there are no cracks, the material is retested using a punch with a smaller size radius. This test is repeated using smaller and smaller radius punches until failure occurs, which determines the minimum R/t ratio of the material. There are other test methods, but this discussion will focus on these punch and die methods.

Figure 1. 90° V-Block Test

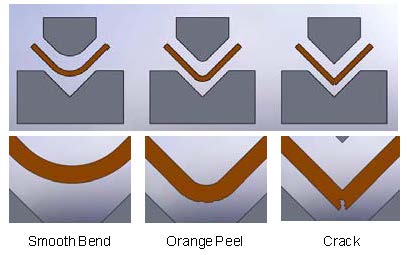

Figure 2. Progressively More Severe Bending

Figure 2 illustrates several possible outcomes of the bend test. With a generous punch radius, strip should bend smoothly on both the inside and outside radii. As the punch radius is reduced, the outside radius begins to show what is called “orange peel.” This is a rumpled texturing of the surface that looks similar to the texture of an orange. Orange peel is not necessarily indicative of cracking. For very inadequate bend radii, the sample will display obvious cracking, and may even break in half during the bend test. If cracking is uncertain, it is helpful to reverse the bend by hand - if cracks occurred in the test bend, the reverse bend will cause the sample to fracture.

There are several factors that determine how well a bend will form. Grain size is important. If a bend is made without stretching the material, the formability is better with smaller grains. If the material is stretched during the bend, then larger grains will provide better formability. The temper (cold work, strain hardening) of the metal also affects its bendability. Higher strength tempers will be less formable than lower strength tempers since ductility is inversely proportional to strength. Annealed tempers will show the best formability, whereas heavily cold worked tempers such as spring and superspring will require much larger bend radii. Thus, alloys that rely on strengthening mechanisms other than strain hardening (cold work, work hardening) have an advantage since they require less cold work to get the same amount of strength as the strain hardened alloys.

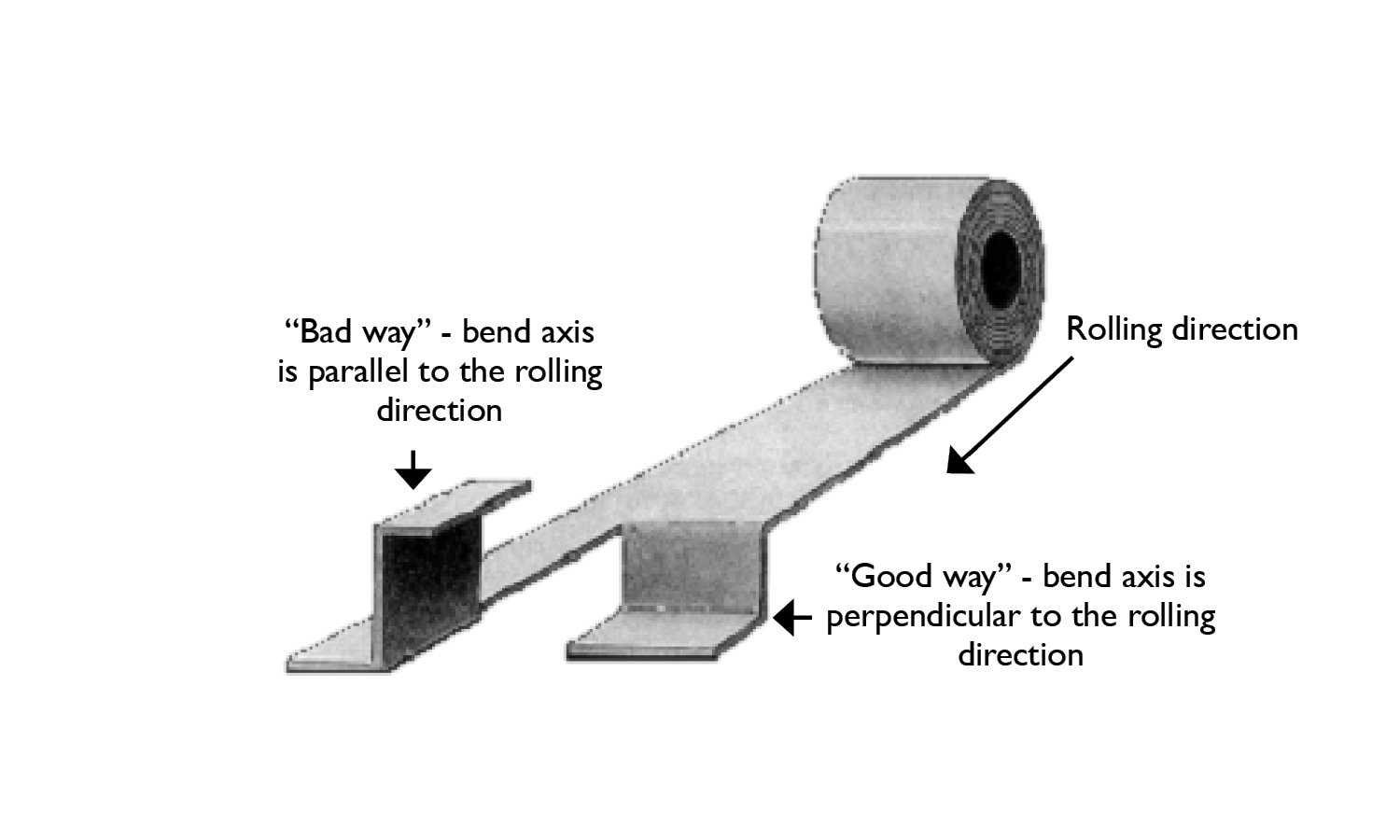

The orientation of the bend relative to the rolling direction of the strip is important. Strip alloys typically are more formable when bends are made in the longitudinal (good way) direction than bends made in the transverse (bad way) direction (Figure 3). Therefore, formability is specified in both the longitudinal and transverse direction. This directionality increases with the amount of cold work in the metal. This is important since many dies are oriented to produce parts with bad way bends.

Figure 3. Longitudinal and Transverse Directions

Unfortunately, the R/t ratio is only an indication of the formability of a material. It does not guarantee that a given bend will actually survive without cracking, even if the R/t ratio is met. It is important to remember that even though this ratio is quoted as a constant for a particular alloy and temper, it may vary depending upon several other factors. Thinner strip will accept slightly smaller bend radii without cracking, and thicker strip will require slightly larger radii. Narrow strip (that with a width less than eight times the thickness) will generally be able to accept smaller radii without failure.

Additionally, the 90° V-block test is very subjective. It is up to the individual performing the testing to determine what constitutes “failure.” For example, will orange peel be considered a failure, or will the test be considered passing until fracture occurs? Secondly, the dynamics of the bend test come into play. With higher punch speeds or greater punch forces the material will be more likely to crack. The punch speed and force will depend on the operator. Furthermore, very few bends are made in stamping dies using 90˚ V-blocks and punches.

There are several other methods of determining formability. A 180˚ bend test is also used, but it is less commonly reported. It should be noted that a 180˚ bend will generally require a larger bend radius than a 90˚ bend, although it is not necessarily twice as large. In some tests a “W” bend test is also used, in which 3 bends are put into the strip sample.

In summary, when choosing a material to use in an application, it is important not to overlook the formability of the material. Since strength and formability are inversely proportional, it is always best to use the highest strength material that meets the formability requirements.

Learn more about our high-peformance materials.

Thanks for joining us for another edition of In Our Element. For ongoing industry updates, connect with us on LinkedIn.