Heat treating copper-beryllium can be a complex process but before we talk about how to heat treat, let’s talk about the reason for using the process. Heat treating is key to the versatility of copper-beryllium alloys. Unlike other copper-base alloys, which get their strength through cold work alone, wrought copper-beryllium gets its high strength, conductivity, and hardness through a combination of cold work and a thermal process called age hardening. Age hardening is also known as precipitation hardening or heat treating—a process that brings out forming and mechanical property benefits that other alloys don’t offer.

Heat treating copper-beryllium alloys is a two-step process made up of solution annealing and age hardening. In this article, I’ll discuss this process and the available copper-beryllium alloys, specific heat treating procedures for wrought and cast products, surface oxidation information, and general solution annealing practices.

Copper-beryllium alloys are available in two basic classes (see Table 1): High Strength Copper Beryllium offers high strength with moderate to good conductivity; and High Conductivity Copper Beryllium has features maximum conductivity and slightly lower strength levels.

*These alloys are supplied only in the mill hardened condition and require no further heat treatment.

Both the high strength and high conductivity copper-beryllium are available as strip in the heat treatable and mill hardened tempers. Mill hardened tempers are supplied in the heat treated condition and require no further heat treatment.

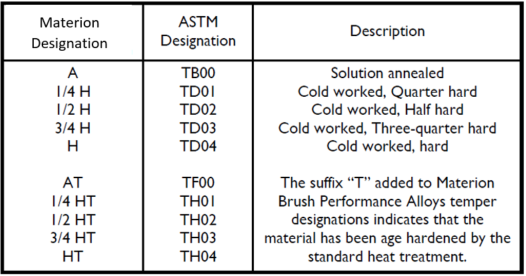

Copper-beryllium is produced in tempers ranging from solution annealed (A) to an as rolled condition (H). Heat treating maximizes the strength and conductivity of these alloys. The temper designations of the standard age hardenable copper-beryllium tempers are shown in Table 2.

During the age hardening process, microscopic, beryllium-rich particles are formed in the metal matrix. This is a diffusion-controlled reaction, and the strength will vary with aging time and temperature.

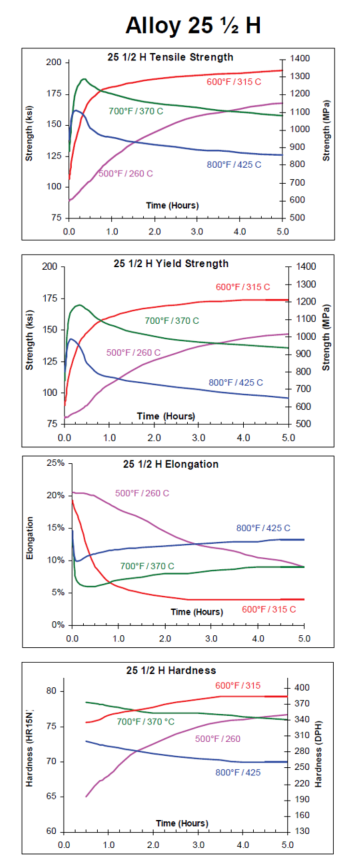

There are recommended or standard age hardening time and temperature combinations for each copper-beryllium alloy, which allow parts to reach peak strength in two to three hours, without the risk of strength decrease due to extended temperature exposure. As an example, the Alloy 25 response curves in Figure 1 show how low, standard, and high aging temperatures affect both peak properties and the time required for the alloy to reach peak strength.

Copper-beryllium can be age hardened to varying degrees of strength. The term peak aged refers to copper beryllium aged to maximum strength. Alloys not aged to maximum strength are underaged, and alloys aged beyond maximum strength are overaged. Underaging copper-beryllium increases ductility, toughness, and uniform elongation. Overaging increases the alloy’s electrical and thermal conductivity, dimensional & thermal stability, and ductility and toughness. Copper-beryllium never ages at room temperature, even if material is stored for significant lengths of time.

Allowable variances in age hardening time are dependent on furnace temperature and final property requirements. To peak age at the standard temperature, furnace time is typically controlled to ±30 minutes. For high temperature aging, however, more precise time control is required to avoid overaging. For example, the aging time of Alloy 25 at 700°F (370°C) must be controlled to ±3 minutes to hold peak properties. Similarly, underaging requires tight control of the process variables because of the sharp initial increase of the aging response curve. In the standard age hardening cycle, heating and cooling rates are not critical, as long as the material remains in the furnace for the proper soak time at temperature

However, to assure that aging time does not begin until parts reach temperature, a thermocouple can be placed on the parts to determine when desired temperature has been achieved.

Standard age hardening times and temperatures for the high-strength copper-beryllium alloys and the high-conductivity copper-beryllium alloys are detailed in the following sections.

Age hardening temperatures for high strength wrought copper-beryllium varies from 500°F (260°C) to 700°F (370°C). The time required to reach peak properties at the lower temperature is longer than at the higher temperature. The standard age hardening treatment is 600°F (315°C) for two to three hours; two hours for cold worked alloys and three hours for annealed alloys. Figure 2 shows the effect of time and temperature on the mechanical properties of Alloy 25 1/2H temper.

The standard age hardening cycle for the high-strength casting alloys, both annealed and as cast, is three hours at 625-650°F (320-340°C). However, to develop the highest strength for the as cast products, a separate solution anneal should precede the age hardening.

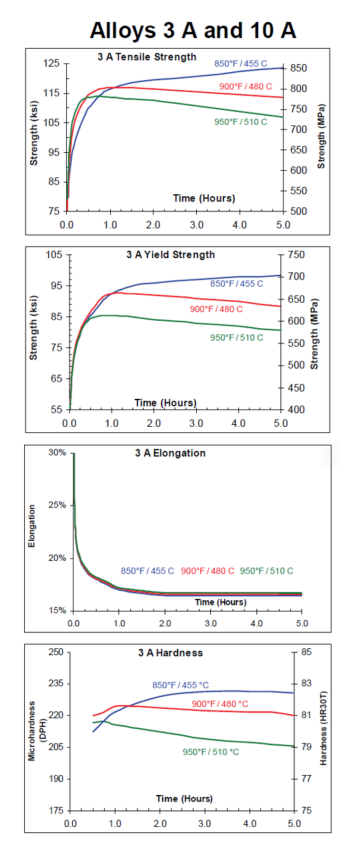

The standard age hardening cycle for both the wrought and cast high-conductivity alloys is 900°F (480°C) for two to three hours; two hours for the cold rolled alloys and three hours for the cast and annealed wrought alloys. The high-conductivity alloys are noted for their excellent electrical and thermal conductivity’s. They obtain their moderate strength through age hardening, but at a higher temperature than the high strength alloys.

Because their mechanical properties change only slightly with time, few high-conductivity applications benefit from either underaging or overaging. As an example, the heat treating curves for Alloy 3 demonstrate the effects of aging on the mechanical properties (see Figure 3).

During aging, the copper-beryllium alloys develop a surface oxide of beryllium and, depending on the alloy and furnace atmosphere, copper oxides, which vary in thickness and composition and are often transparent.

Surface oxidation of beryllium during age hardening cannot be suppressed, even in a pure hydrogen atmosphere or a hard vacuum. Some atmospheres can minimize the copper oxidation, like a low dew point (-40°F/-40°C) atmosphere of approximately 5 percent hydrogen in nitrogen, which also economically aids in heat transfer. Air atmospheres contribute the most to surface oxide and reducing atmospheres the least. Even though oxide films are not detrimental to the base alloy, they should be removed if parts are to be plated, brazed, or soldered. In order to prevent excessive oxidation or tarnishing when taking heat treated parts out of the furnace, the parts should be allowed to cool below 65°C (150°F) before removal.

To elicit an effective age hardening response, copper beryllium must be solution annealed and quenched prior to aging. In addition to preparing the alloy for age hardening, annealing softens the alloy for further cold work and regulates grain size. Materion performs this required anneal on all wrought products at the mill. Therefore, customers usually do not need to anneal prior to age hardening. Furthermore, solution annealing will cause expansion and distortion of machined parts and can cause generation of hazardous oxides on the surface.

If solution annealing is required, it is a high temperature soak: 1450°F (790°C) for the high strength alloys and 1650°F (900°C) for the high conductivity alloys. Annealing must be carefully controlled as excess time or temperature may cause grain growth. Solution annealing should be immediately followed by a water quench. As a precaution, large quantities of metal should not be annealed without first conducting a furnace simulation test. Thin sections, such as fine wire, require an annealing time of about 3-5 minutes. Fifteen minutes to one hour is required for thin walled tube and small castings. Heavy sections (above about one inch) usually require 1-3 hours. A heat up time of one hour per inch of thickness must be added to the soak time.

Because most salts will attack copper-beryllium at temperatures in the solution annealing range, solution annealing should not be performed in a salt bath.

When peak aging copper-beryllium castings and weldments, the customer must always solution anneal prior to age hardening. However, if peak properties are not required, castings can be age hardened from the as cast condition without the solution anneal.

In applications not requiring severe forming, fabricators can eliminate the heat treating and cleaning of the heat treatable alloys by specifying mill hardened copper beryllium.

To learn about the safe handling of copper beryllium, please visit www.materion.com/

Processing beryllium-containing alloys poses a health risk if safe practices are not followed. Inhalation of airborne beryllium can cause serious lung diseases in some individuals. Occupational safety and health regulatory agencies worldwide have set mandatory limits on occupational respiratory exposures. Read and follow the guidance in the Safety Data Sheet (SDS) before working with this material. The SDS and additional important beryllium health and safety information and guidance can be found at berylliumsafety.com, berylliumsafety.eu and Materion.com. For questions on safe practices for beryllium-containing alloys, contact the Materion Product Stewardship Group at +1.800.862.4118 or contact us by e mail at Materion-PS@Materion.com.