By: Bob Dixon, Product Line Director, Electronic Materials

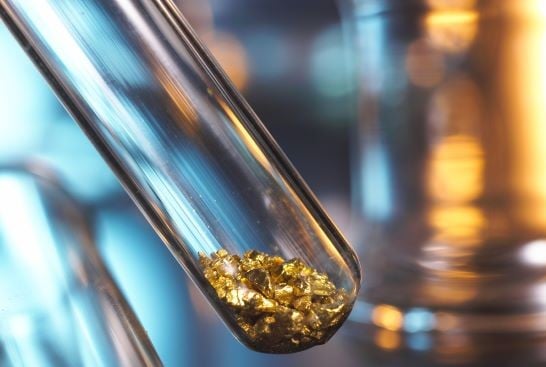

Materion is one of very few companies that consistently refines gold to the 99.999% purity level required by some of the most advanced high-tech companies. The largest use of these high-purity source materials is in our customer’s production of thin films using physical vapor deposition (PVD). In PVD processes, the film is formed by atoms transferring directly from the source through a gas phase and onto the substrate. The two technologies utilized most frequently for these PVD processes are e-beam evaporation and sputtering.

During evaporation and the process of being deposited as a thin film onto a semiconductor wafer, gold can be prone to eject droplets that solidify into solid particles on the wafer. This leads to improper functioning of a microelectronic circuit and requires the scrapping of whole production lots.

Materion has been very successful in reducing this behavior, technically referred to as “spitting,” by developing the proprietary EVAPro® process. EVAPro is a proprietary manufacturing process that deactivates this material while producing ultra-high-purity evaporation materials with low organic and inorganic impurities to ensure superior surface cleanliness. This enables customers to increase yields and tool uptime.

What factors contribute to the defect-causing behavior known as “gold spitting” during the evaporation process and what can be done to prevent it? As previously stated, gold can be prone to eject droplets that solidify into solid particles on the component. In a previous technical paper presented at the International Conference on Compound Semiconductor Manufacturing Technology (CS Mantech Conference), Materion addressed this common industry problem along with potential solutions during an award-winning presentation.

In the paper written by our team, "Developing a Fundamental Understanding of Gold Spitting During Evaporation," Materion considers factors that can contribute to this common phenomenon. During evaporation processes, and in particular, the process of being deposited as a thin film onto a semiconductor wafer, for example, gold can be prone to eject droplets that solidify into solid particles on the wafer, otherwise known as "spitting."

In the Poster Session of the Show, Materion’s presentation was honored as the “Best Poster Award” by ballot vote of conference attendees. The popular poster generated high traffic and many discussions with process engineers from within the compound semiconductor industry, assessing how gold spitting can significantly impact sputtering yields and product quality.

The highly controlled, gold spitting experiments were conducted at the former Materion Applications Laboratory in Westford, MA. The lab studies discovered the factors that contribute to spitting can be divided into two broad groups: 1) evaporation process parameters and 2) material quality. If these parameters are not carefully regulated, a process results with significant variation in spitting. For a controlled process, the quality of the gold (Au) plays a significant role in the degree of spitting, the purity and cleanliness of Materion’s Au reduces the amount of spitting. View the full technical paper here.

We have also developed proprietary techniques to enhance the performance of other high-purity and specialty products such as sputtering targets, specialized wire and strip materials provided to microelectronics manufacturers and other markets. In sputtering applications, the uniformity of the deposited thin films is critical to the performance and cost of the device. Super Fine Grain (SFG™) is a manufacturing process that optimizes the structure of Materion’s sputtering targets. Properly controlling the grain and crystal orientation of the target results in higher-yielding, more consistent deposition for our customer’s end products.

“Our use of ultra-pure gold, plus these processes and others, are all part of our full lifecycle precious metals management service,” says Bob Dixon, Materion Product Line Director/Precious Metals. “By integrating refining, product manufacture, precision parts cleaning and recycling into a closed loop, we are able to significantly reduce our customer’s total cost of ownership over the precious metal lifecycle.”

Gold Refined to High Purity Level. Learn about the technology to refining gold and why it's so beneficial to high quality product development in key markets.