The James Webb Space Telescope is a mechanical eye so penetrating it will look back in time to the dawn of the universe. And its cornea of lightweight, durable mirrors is largely to thank for all we’ll learn from the images it sends back to Earth.

The James Webb Space Telescope is a mechanical eye so penetrating it will look back in time to the dawn of the universe. And its cornea of lightweight, durable mirrors is largely to thank for all we’ll learn from the images it sends back to Earth.

The telescope will peer into space from almost a million miles from Earth, orbiting a Lagrange point, where the combination of the sun’s and Earth’s gravity creates a relatively stable parking spot. For observations, it will rely on a set of gold-coated mirrors capable of handling punishingly cold temperatures to collect radiation emitted by the earliest stars.

NASA couldn’t use glass for Webb’s mirror as it did for the Hubble Space Telescope’s mirror, which operates at room temperature. Detection of faint infrared light—actually heat emitted billions of years ago—requires the near absence of heat in its instruments. The Agency needed a lightweight, durable material that would maintain a stable shape at temperatures approaching absolute zero and that could withstand the hazardous journey into space.

“We had to pick a material we knew we could make at room temperature, and we knew it would change shape as it went cold but would do so in a predictable and consistent way every time,” recalls Paul Geithner, a deputy project manager for Webb based at Goddard Space Flight Center. “Beryllium is a really good material for that. It’s really stiff and, once it gets below about -300 °F, it basically stops shrinking.”

This is important because Webb, insulated by a sun shield, will operate at about 30 K (-406 °F) and only experience temperature swings of plus or minus 30 K, never reaching a temperature that would cause it to expand.

Beryllium also has a higher stiffness-to-mass ratio than other materials, “which wasn’t a selection criteria but is an advantage, as it means you get a lighter mirror, better able to withstand the high vibro-acoustic levels during takeoff,” notes Lee Feinberg, the telescope manager for Webb at Goddard.

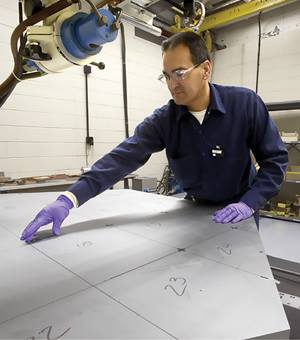

When NASA was planning the telescope, Mayfield Heights, Ohio-based Brush Wellman, now known as Materion Corporation, was one of the top beryllium-producing companies in the world. The company owns a major bertrandite mine in Utah and had perfected the process of treating beryllium and crafting it into the kind of light but sturdy mirrors NASA needed for Webb. After a bidding process, Materion won the contract to build the mirrors.

Read the rest of the NASA Spinoff article on the benefits of beryllium and the technology transfer potential.