Copper-beryllium is a precipitation hardenable copper alloy. This means that it derives most of its strength from heat treatment as opposed to the cold work that is exclusively relied upon by most other copper alloys. Copper-beryllium alloys possess a great advantage by providing a combination of high strength, good conductivity and excellent formability. The heat-treating step also provides copper-beryllium alloys with excellent resistance to stress relaxation, compared to the standard cold worked copper alloys. Let’s take a look at the different types of copper-beryllium alloys before discussing how you can select the right temper for your application.

There are two classes of copper-beryllium alloys. The high-strength copper-beryllium alloys (our Alloys 25, 190 and 290), which have the highest strength of any copper alloy, are widely used in electronic connectors, switches and springs. These high-strength alloys have electrical and thermal conductivities that are about 20% of pure copper. The high-conductivity copper-beryllium alloys (our Alloys 3, 174, Brush 60®) have about 50% of copper's conductivity at a lower strength level, and are used in power connectors and relays. Alloys 390® and 390E feature the strength of the high-strength alloys coupled with the conductivity of the high-conductivity alloys.

Copper-beryllium is strengthened primarily by heat treatment. It is available in two forms – age hardenable and mill hardened. In the age hardenable form, the material is soft and ductile. It will form easily. It must then be heat treated to full strength and conductivity after the forming operations are complete. In the mill hardened form, the material is age hardened at the mill, so no further heat treatment is required. (In other words, it is purchased in the partially age hardened state.) However, the formability at a given strength level will not be as good as that of the heat treatable material.

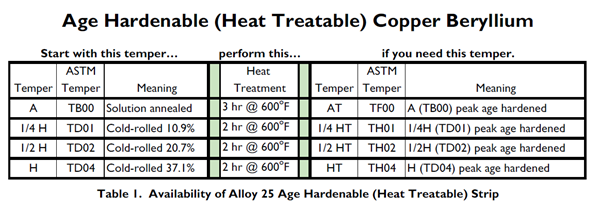

Alloy 25 is the age hardenable high strength copper-beryllium alloy. Once it is heat treated, it will have a strength unsurpassed by any other copper alloy. Alloy 25 is available as solution annealed (the softest, most formable state) and cold rolled to various strength levels (¼ H, ½ H and H). The ¼, ½ and full hard designations refer to cold work only and have nothing to do with heat treatment. After aging for the proper time and temperature, the solution annealed (A) temper becomes AT. Similarly, the ¼ H becomes ¼ HT, the ½ H becomes ½ HT and the H becomes HT. These are the only outcomes of proper age hardening. It is not possible, for example, to heat treat ¼ H material to the ½ HT or HT conditions. Furthermore, Alloy 25 is not available in strip form in the age hardened (pre-heat treated) condition. This means that it is not possible to purchase Alloy 25 strip in the AT, ¼ HT, ½ HT or HT forms. It can only be purchased in the A, ¼ H, ½ H or H forms and then heat treated accordingly after forming. Once it is heat treated, no additional forming is possible, since it will be at maximum strength and minimum ductility (i.e., it will be too “brittle” to form). Please see Table 1 for reference. (Additional temper information is available in ASTM B601.)

If the high strength of Alloy 25 is desired, but heat treating is an obstacle, then mill hardened material should be purchased. The mill hardened versions of Alloy 25 are called Alloy 190 and Alloy 290. (All three alloys have the same composition but are processed very differently and have different properties.) Alloys 190 and 290 are partially aged to less than peak strength and hardness before leaving the mill.

The strength to formability ratios of Alloys 190 and 290 will not be as good as that found in Alloy 25. The lowest strength tempers of 190 and 290 will have very good formability. At increasing levels of strength, however, the formability becomes progressively more limited. Alloy 190 XHMS is the strongest mill hardened temper, with a strength nearly equal to Alloy 25 HT. However, its limited formability restricts its use to flat or nearly flat parts.

The high conductivity copper-beryllium Alloys 3, 174, Brush 60®, Alloy 390 and 390E are available in mill hardened form only. No heat treatment needs to be performed on these alloys. However, the temper designations of these alloys is different from the high strength Alloy 25. In Alloy 25, age hardenable tempers end in A or H (solution annealed or cold worked) or in AT or HT (heat treated). The mill hardened Alloy 190 tempers end in AM or HM and the Alloy 290 tempers follow the modern ASTM convention of beginning with TM. The high conductivity alloys all end in HT, not HM. (This is a carryover from an obsolete age hardenable high conductivity alloy whose properties were identical whether it was mill hardened or age hardened after forming.)

The first step in selecting a material is to decide on the high-strength or the high-conductivity family. If high strength is required, select Alloy 25 only if heat treatment after forming is a viable option. If it is not an option, or if the parts are very thin and thus susceptible to age hardening distortion, then Alloy 190 or 290 would be the proper choice. If current carrying capacity is an issue, then Alloy 3, 174, Brush 60, 390 or 390E would be the appropriate choice.

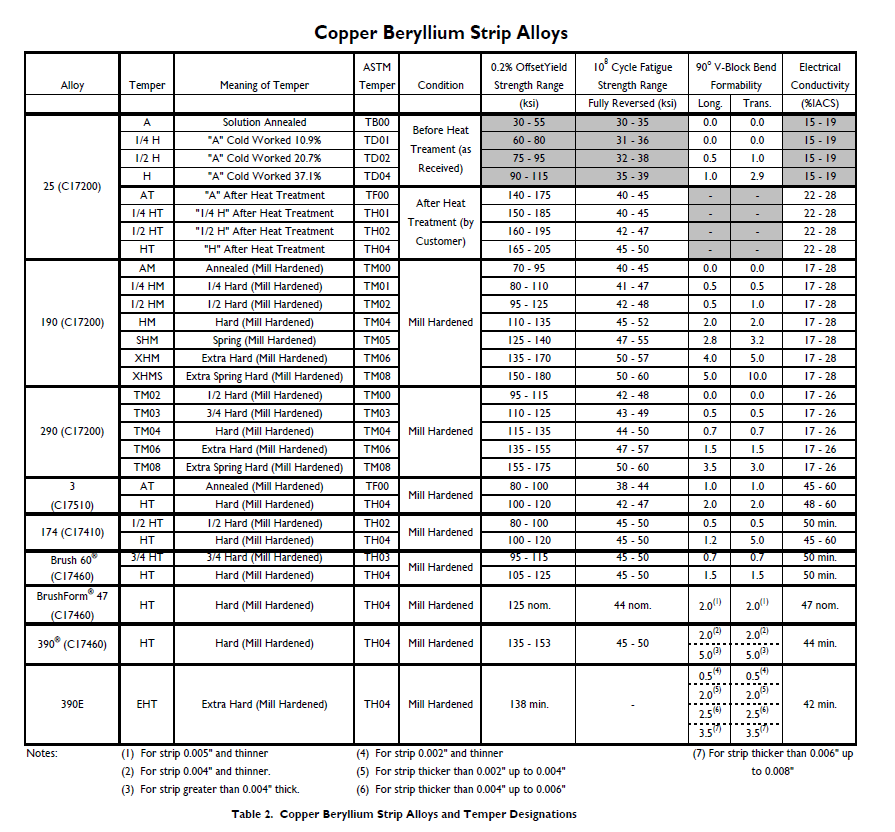

Once the alloy is selected, the next step would be to select the temper. This can be done by determining the maximum stress in the part and then selecting a material with a yield strength that exceeds this value. (If the part is subjected to cyclic loading, then the fatigue strength should be used instead of the yield strength.) If the stress level is unknown, then simply choose the highest strength temper that meets the formability requirements of the design. Table 2 lists the yield strength, fatigue strength, conductivity and formability of all the copper beryllium strip alloys. The meaning of each temper also is listed in the table. Please note that the temper designations for the age hardenable material are precisely defined. However, the temper designations for mill hardened material are not. This allows for proprietary processing.

Thanks for joining me for another edition of In Our Element. For ongoing industry updates, connect with me on LinkedIn.

Processing beryllium-containing alloys poses a health risk if safe practices are not followed. Inhalation of airborne beryllium can cause serious lung diseases in some individuals. Occupational safety and health regulatory agencies worldwide have set mandatory limits on occupational respiratory exposures. Read and follow the guidance in the Safety Data Sheet (SDS) before working with this material. The SDS and additional important beryllium health and safety information and guidance can be found at berylliumsafety.com, berylliumsafety.eu and Materion.com. For questions on safe practices for beryllium-containing alloys, contact the Materion Product Stewardship Group at +1.800.862.4118 or contact us by e mail at Materion-PS@Materion.com.