With each release of the latest handheld electronics, consumers have come to expect enhanced functionality, more powerful chipsets and greater durability in devices that are also smaller and thinner. This trend presents design challenges because handheld devices are limited in the ways they can maintain proper operating temperatures. Most rely exclusively on passive cooling systems.

We developed eStainless® clad to address market-wide structural and heat management requirements and to enhance or enable next-generation smart phones designs and technologies such as 6G and virtual reality.

While stainless steel is commonly used in mobile devices because of its stiffness and strength, its poor conductivity requires additional materials to be used as heat spreaders to manage increasing thermal loads and avoid battery hot spots.

eStainless clad materials are ideally suited for frames, brackets, chassis and housings in electronics. With 10 to 18 times higher thermal conductivity than steel, and comparable strength and stiffness properties, eStainless clad materials can be integrated as a drop-in replacement with existing components.

Download our eStainless data sheet to learn more.

ESTAINLESS CLAD FRAME AND CHASSIS COMPONENTS DISSIPATE HEAT

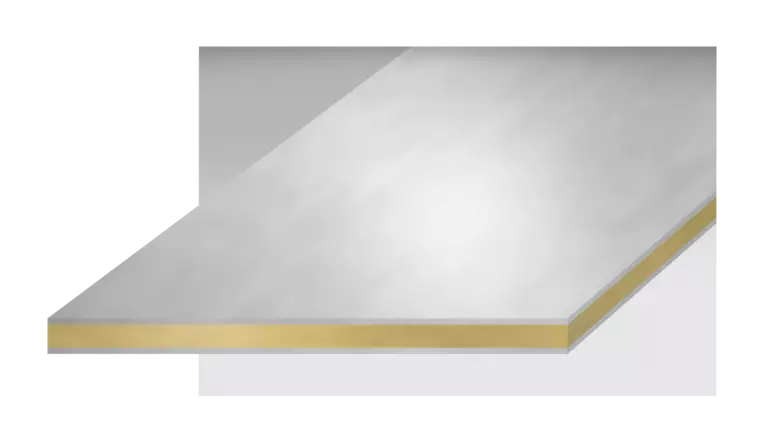

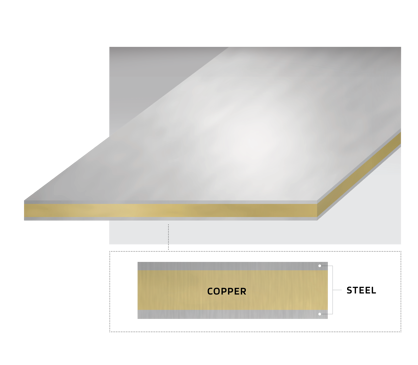

Adding heat spreading material increases the overall size and weight of electronic devices. Our eStainless clad materials serve a dual purpose, enabling thin, stiff structural components that also conduct and dissipate heat. They are thermally conductive, fully formable clad laminates made of stainless steel and copper (Cu) or aluminum (Al). eStainless clad Cu (SUS/Cu/SUS) is ideal as a high conductivity replacement for stainless steel, allowing heat spreading functionality to be designed directly into the structure of devices.

More even temperature distribution enhances energy transfer away from the surface, allowing eStainless clad to dissipate more heat.

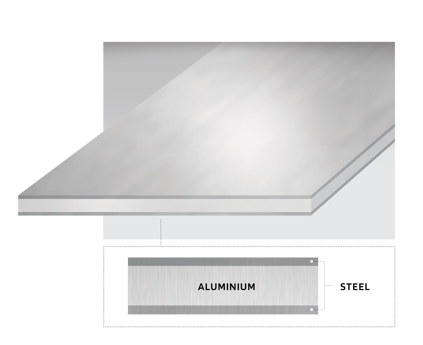

eStainless clad Al (SUS/Al/SUS) can replace thicker aluminum components, allowing for device lightweighting without sacrificing strength or thermal requirements. Integrated heatsinks made of eStainless clad reduce the need to add specialty thermal management solutions, saving both costs and internal device space.

Compare the unique property benefits of both eStainless clad Cu and eStainless clad Al.

Benefits

- Reduce z-height vs. stainless steel & graphite

- Superior heat spreading properties

- Mechanical performance rivaling solid steel

- High stiffness-to-weight ratio for lightweighting

- Improved heat spreading vs. stainless steel & graphite

- Fully formable for stamping & drawing

Applications

- Smartphone frames, brackets, chassis & housings

- 5G & 6G connectors