Automotive electronic circuitry and sensors require materials that can withstand high power environments to ensure reliability. While many of the metal structures within the circuit, known as lead frames, are created using plated metals, cladding offers a more durable, high performing solution. Materion's lead frame clad materials incorporate stable wire bondable surfaces and conductive terminal alloys for signal and power management. Produced in reel-to-reel processes, our semi-finished lead frame materials enable large volume manufacturing of high reliability electronic packaging materials.

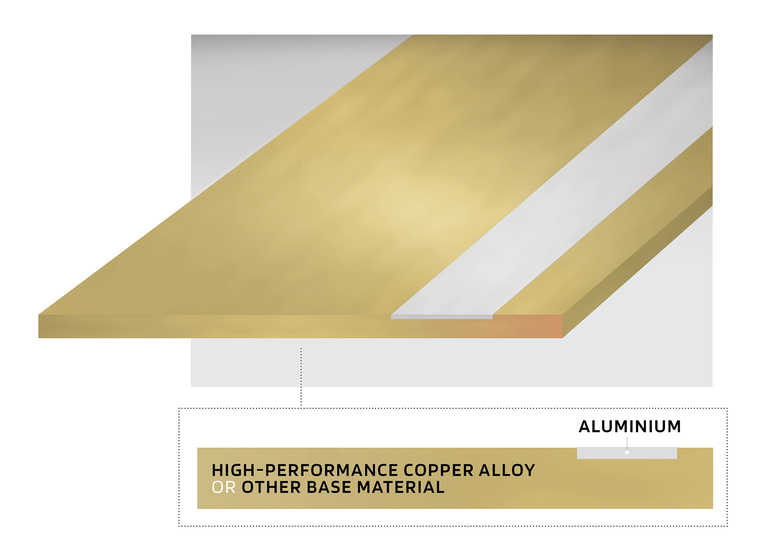

ALUMINUM INLAY CLAD FOR ULTRA-STABLE BONDING

Wire bonding forms the connection between microelectronic circuitry and the macro-scale wiring systems of passenger cars. In these applications where reliability and high-power linkages are critical to a control module, bonding aluminum wire to aluminum pads offers the highest processing yields. Integrating the aluminum pad directly into the lead frame via inlay cladding is the ideal process for safety critical applications, such as electronic power steering modules and anti-lock brake systems.

ELECTROPLATED ALTERNATIVES TO INLAY CLAD

We also offer a variety of electroplated lead frame designs, which offer a cost-efficient solution for many electronic modules and sensors. Electroplated nickel-phosphorous, for example, is available as overall or selective stripe plating and is commonly combined with other electroplated materials such as selective tin or silver for contact terminals.

Benefits

- High temperature & vibration stability

- Softening resistance of 250°C minimum

- Non-toxic, lead-free materials

- Designed for manufacturability

Applications

- Power steering modules

- Anti-lock brake systems