There are many advantages of using copper-beryllium (CuBe) alloys in demanding end-use applications, including high strength, conductivity, hardness and corrosion resistance. Our CuBe products are available in rod, bar, wire, tube, plate, strip, forgings, and extrusions in different compositions and unique property sets to meet the requirements of a range of demanding markets and applications.

When high strength is your top priority, the following copper-beryllium alloys from Materion can meet your specific needs.

ALLOYS 25, M25 AND 165

Alloy 25 provides the highest strength of all available copper-beryllium alloys. It has electrical and thermal conductivity considerably greater than other high-strength copper alloys with an ultimate tensile strength that can exceed 200 ksi (1380 MPa), hardness approaching HRC 45, and a minimum electrical conductivity of 22% IACS (International Annealed Copper Standard).

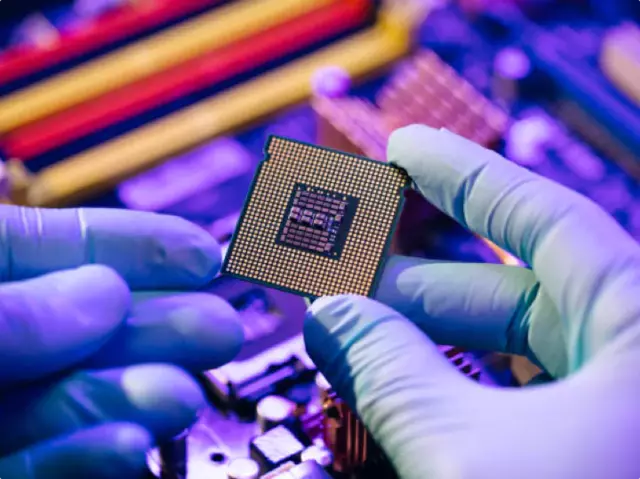

Alloy 25 is available in strip, rod, tube, wire, bar, plate, forging and extrusion forms. Alloy 25 is a versatile material used in a broad range of applications from oil and gas drilling components to aerospace bushings, automotive connectors and computer processor socket contacts. Download our Alloy 25 data sheets for more details.

Alloy M25, which is available in rod and wire forms, offers similar strength to that of Alloy 25, but provides greater machinability with the addition of lead. This alloy is ideal for contacts for electronics, aircraft and automotive applications. Download our Alloy M25 data sheets for more details.

Alloy 165 provides strength nearly as high as Alloy 25, but with a slightly lower beryllium content. It is available in bar, plate, tube, forging and extrusion forms. Alloy 165 is used to make bushings, bearings, resistance welding components and undersea instrument housings for telecommunications. Download our Alloy 165 data sheet for more details.

NEW MACHINABLE, HIGH-STRENGTH EMERY LOW LEAD ALLOY

Materion has introduced its newest high-strength copper alloy product, Emery Low Lead™ alloy (UNS C17210), a RoHS compliant material with less than 0.1% lead. This new material is superior to other easily machinable copper alloys, providing the same high strength, good conductivity, machinability and reliability of our M25 product, but with significantly lower lead content.

With the high-strength properties of steels and the high conductivity of copper, Emery Low Lead copper-beryllium alloy outperforms other low lead alloys in demanding electronic applications. The material is ideal for circular connectors, coaxial connectors and test probes, and it can be used as a replacement for lower strength lead-containing materials such as phosphor bronze.

Emery Low Lead alloy is the result of a multi-year Research & Development program. Materion engineers developed and evaluated several potential compositions for performance and machinability. In tests at machine shops and our customers’ facilities, Emery Low Lead alloy maintained its high strength and performed best in multiple types of machining operations.

Emery Low Lead alloy is available in rod and wire.

While similar to M25, some adjustments may be necessary to optimize machine settings for Emery Low Lead alloy. To learn more, read our Emery Low Lead Machining Guidelines or talk with our Customer Tech Support engineers.

Download our Emery Low Lead Alloy data sheet for details.

ALLOY 190 AND 290 STRIP MATERIALS

Materion's high strength, mill hardened copper beryllium (UNS C17200) strip materials, Alloy 190 and Alloy 290, provide the highest strength of any mill hardened copper alloy, combined with electrical conductivity considerably greater than other high strength copper alloys.

Alloy 190 is flatter and better for precision strip applications and operations such as photochemical machining that are sensitive to shape. Alloy 190 does not require heat treatment and offers tensile strength up to 190 ksi (1310 MPa). Alloy 190 is an outstanding material for automotive terminals, components for medical connectors, battery contacts and contacts for switches and relays. To learn more, download the Alloy 190 data sheet.

Alloy 290 has greater formability than Alloy 190 and is most often used to fabricate high reliability components that require complicated connections without losing strength. Alloy 290 can be bent and reformed into specially shaped electrical connectors, board-to-board contacts and spring contacts for batteries. Alloy 290 is a cost-effective alternative to conventional mill hardened products. To learn more, download the Alloy 290 data sheet.

BRUSHCAST ALLOYS

Our BrushCAST® copper-beryllium casting alloys meet tough technical specifications with high strength and good electrical conductivity, wear and galling resistance. As cast products, they also provide excellent replication of cast detail, making it ideal for plastic mold making, non-sparking safety tools, parts for defense applications and undersea components.

BrushCAST casting alloys are available in several chemistries. The versions noted as CT indicate the addition of titanium, producing casting alloys with smaller material grains, improved machinability and polishability. Depending on alloy selection, BrushCAST alloys are available as casting ingots or master alloys in ingot and shot forms.

Download the BrushCAST datasheets to learn more about the following high strength products:

- Alloy 165C / Alloy 165CT

- Alloy 20C / Alloy 20CT

- Alloy 21C

- Alloy 275C / Alloy 275CT

To access more of our technical resources on copper-beryllium alloys, please visit Resources.

Benefits

- High strength

- Electrical conductivity

- Good formability for complex shapes

Applications

- Oil & gas drilling equipment

- Aerospace bushings & bearings

- Industrial wear plates

- Circular & coaxial connectors