Materion designs and manufactures high precision dielectric and metal thin-film optical coatings for a variety of applications. With nearly a century of experience in coating technology and our optical component manufacturing knowledge, we are able to deliver coatings on substrates supplied by our customers. Based on our know-how, we can offer the full coating service, the coating designs, the substrate preparation and the final layer qualification according to parameters. The fully qualified solution is ready to be directly implemented into your final product.

Our optical technology enables high-performance applications like adaptive cruise control, head-up displays, and intelligent headlights. We utilize several advanced coating technologies for all major thin-film coating types used in the precision optics and photonics industry. A broad range of processes individually optimized for the various coatings and the customer's specific requirements are used for manufacturing of optical components. State-of-the-art facilities with clean-room environments together with tailor-made cleaning technologies to prepare the surfaces ensure high quality and consistency of the coatings. Spectral photometry and various other inspection methods are used to ensure that all customer specifications and requirements are met.

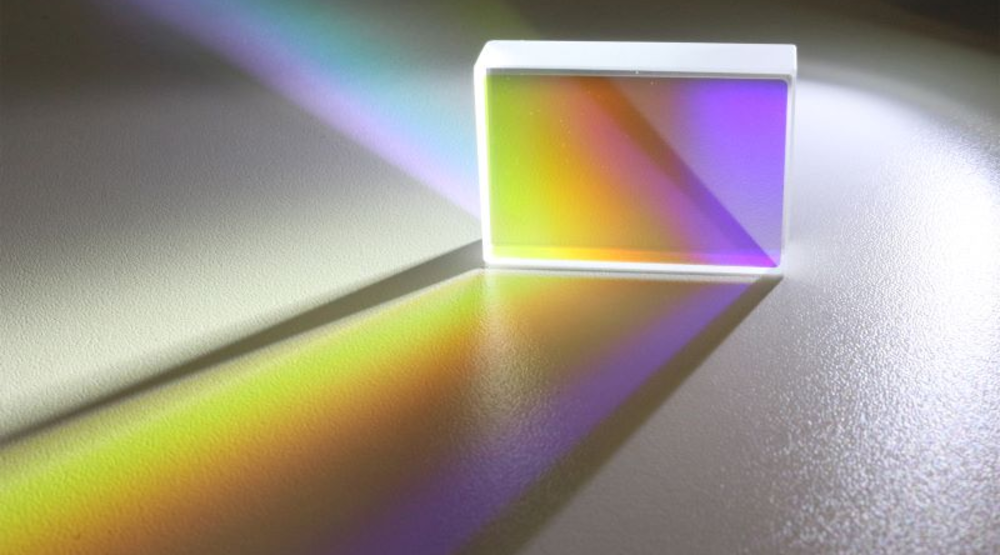

Our high-precision dielectric and metal thin-film optical coatings utilize several advanced coating technologies to hit the exact specifications you require.

The most popular coatings include anti-reflection, conductive and transparent, dielectric, metallic, low defect, patterned, gradient and coatings on plastics. Beyond these category groups, we can also work with you on customized coatings.

Learn More