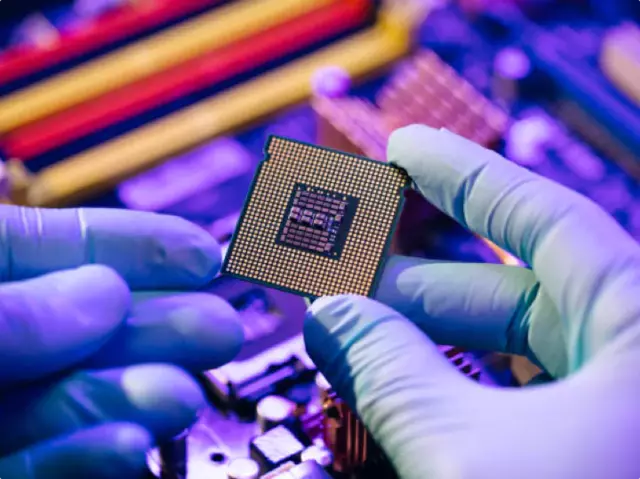

Materion produces high-purity tantalum targets and plates to support advanced-node logic and memory devices in the ever-growing semiconductor industry. Finished targets from our internally fabricated plates sputter uniformly thin layers of tantalum onto silicon wafers being used in next-generation logic chips like DRAM and 3D-NAND.

Vertically integrated, our in-house, end-to-end process encompasses everything from melting and machining to heat treatment and recycling of tantalum. We offer the industry’s widest portfolio of melted and sintered tantalum products.

- Melted Tantalum Process: superior texture control and custom microstructure based on customers' processes, with more than 10 generations available.

- Sintered/Powder Metallurgy Tantalum Process: premium texture control within target and target-to-target, providing exceptional process control.

Our tantalum is available in >99.995% purity with chemical and metallurgical uniformity, and is available in a variety of forms, including sputtering targets, plates, coils, and pots.

REMARKABLE CONSISTENCY, HIGH REPEATABILITY

With decades of expertise in high-volume production of texture- and microstructure-controlled tantalum for sputtering targets, our team of highly skilled R&D scientists and engineers partners with our customers to meet their customized specifications and process needs.

The result? High-volume-manufactured disks with exceptionally consistent properties and proven plate-to-plate repeatability.

BEST-IN-CLASS PRODUCTS, IN-HOUSE VERTICAL PROCESSING CAPABILITY

Our state-of-the-art facility in Dangjin City, South Korea, produces fully finished tantalum sputtering targets with materials sourced from our Newton, Massachusetts (U.S.) site. This strategic site expands our global footprint and allows us to better serve semiconductor industry customers around the world.

Benefits

Performance

- Decades of expertise in high-volume production of texture-controlled tantalum for sputtering targets

- Ability to tweak microstructure to suit customer needs, offering more than 10 generations of target compositions

- Vertically integrated, in-house manufacturing

- In-house ISO-17025 certified laboratories providing customers with comprehensive analytical testing

Cost of Ownership

- Performance consistency leading to improved die-level yield

- Highly consistent sintered products allowing for faster qualification, less cost

- Customized melted products tailored to very specific customer needs

ESG

- Extensive recycling capability

- Conformant tantalum products

- RMAP certification (RMAP certification)

- Raw material compliance with RBA/RMI

- Non-DRC/Rwanda/China material available (DFARS compliant)

Applications

- Logic

- DRAM

- 3D-NAND Memory