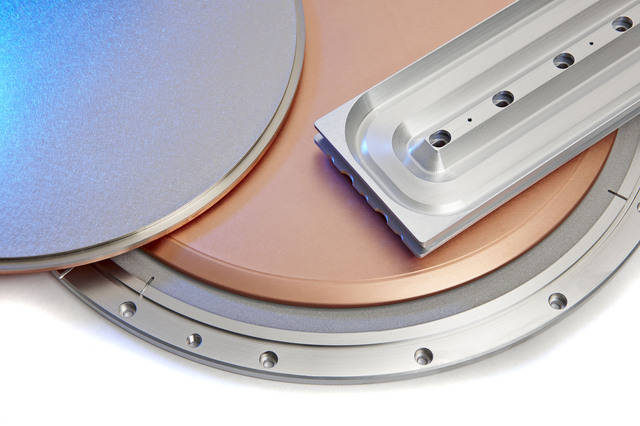

Our sputtering targets meet production requirements for uniformity, reproducibility and homogeneity in glass, web, electronic, semiconductor, photovoltaic and display coatings. We offer a wide variety of precious and non-precious metal targets and customize precision alloy compositions to ensure thin film coatings with consistent phase content and refined grain size.

EXCEPTIONAL SPUTTERING TARGET ADVANTAGES

Materion's deep experience with sputtering targets and extensive material control result in:

- Unique designs and forms to reduce cost and increase uptime

- Size and design customization up to 13.2 ft length (4 meters)

- Fine-grained targets that deliver uniform thin film coating

- Ceramic and inorganic targets with customized chemistries

- High-purity source materials with superior surface cleanliness

SPUTTERING TARGET TYPES

We offer specialty targets that address the mass production challenges of thin film coating of large surface areas for residential or architectural glass.

- Large-Area Sputtering Targets are custom designed for optimal large area thin film coating coverage

- ME Grade® Sputtering Targets are magnetically enhanced to resolve challenges with ferromagnetic materials design

- Rotatable Sputtering Targets provide higher material utilization using cylindrical targets

- Proprietary CORA® material

MORE ON CORA

Our CORA material is a corrosion-resistant silver alloy sputtering target used in the manufacture of OLED flat-panel screens, video and automotive displays, and transflective displays. This durable material comes in a range of sizes with small grain. This in turn enhances the luminance and longevity of screen displays, delivering highly uniform film properties over large form factors and increasing yield.

LEARN MORE

Please download our sputtering targets brochure to learn more and access greater technical detail.

Benefits

- We are a leading innovator with more than 25 years' experience in producing large-area and rotary targets, specializing in customized solutions.

- We have world-class laboratories with the most comprehensive analytical testing.

- We offer industry-renowned technical experts to assist customers in developing application-specific solutions.

- We also offer full-service precious metal management to help lower total cost of ownership.

Applications

- Architectural glass

- Automotive glass and displays

- Commercial and industrial glass

- Electronics

- Electrochromic glass

- Electrolysers

- Medical

- Aerospace and defense

- Semiconductor,

- OLED display coating

- And more