The materials and deposition processes employed to make coatings that are intended for use at wavelength regions between UV and far IR are described in this overview of the technology. Coatings composed of special materials are deposited as nano- and micro- meter thicknesses by specific techniques to control the optical, mechanical, chemical and electrical properties of optical surfaces.

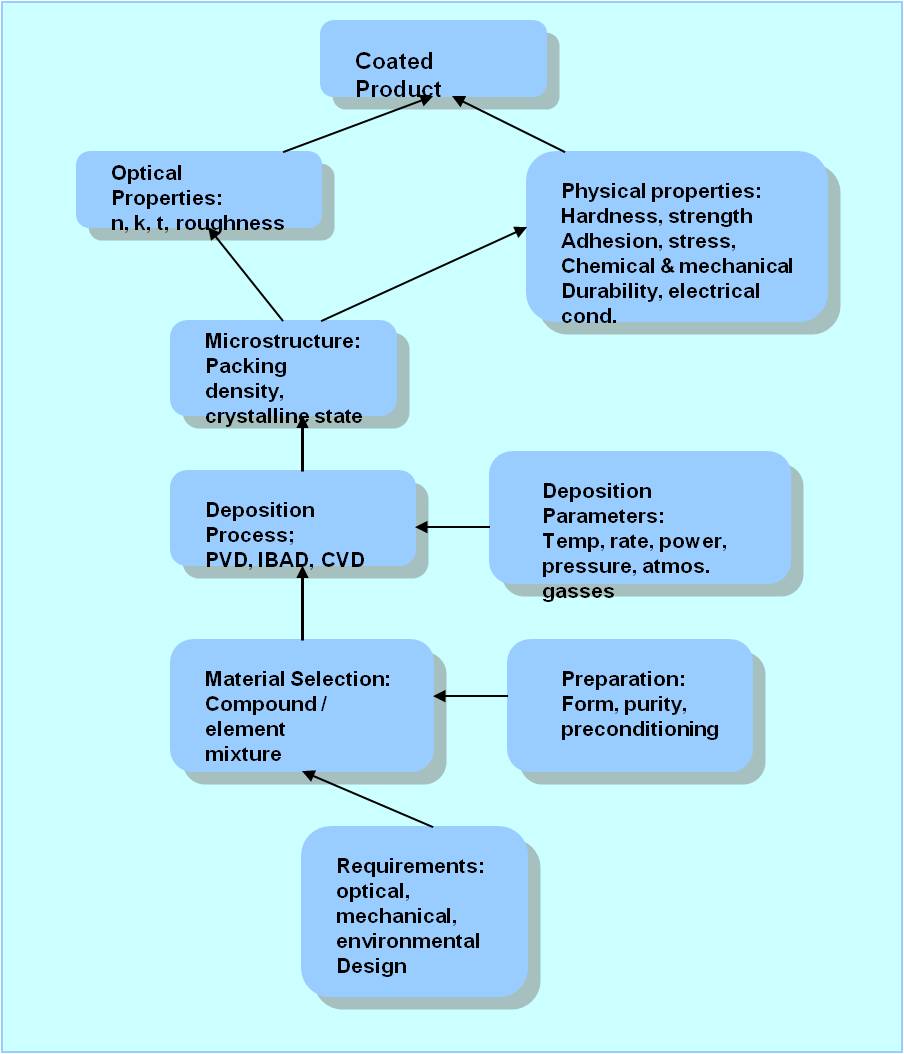

The components of the deposition process, starting with the performance specifications and continuing through the finished coated surface, are diagrammed in Figure 1. It is evident from the number and descriptions of the process components that material science and deposition technology play complex interdependent roles in the overall process of producing optical coatings.

It is important for the system designer to understand the individual components of the process and their interactions. When presented with the spectral and environmental requirements and the substrate material to be coated, the coating engineer has the responsibility of selecting the appropriate coating materials and deposition process. A thin-film design is then generated that includes the wavelength dependencies of the optical constants, refractive index and extinction coefficient - quantities that need to be pre-determined for specific materials and their deposition process parameters. From this theoretical layer-by-layer design, the performance is predicted and evaluated with respect to spectral coverage, incidence angle, surface shape, substrate temperature constraints, mechanical durability and verification measurement.

The technology of preparing the coating material is equally complex and includes consideration of such factors as chemical composition, form, and deposition technique. The starting form of the coating material and its preparation are selected by the engineer based on the deposition technique available and the design prescription. The deposition process’ operational parameters, previously determined for each material, are programmed into the deposition controller along with the coating design. These deposition parameters, coupled with material behavior, will determine the physical micro-structural properties of the thin-film layer. In turn, the film properties determine the optical, mechanical and environmental properties of each deposited layer.

Figure 1. Components of the deposition process of an optical thin film.

The next sections discuss further details related to materials and their applications, and deposition processes.