INNOVATIVE RESEARCH AND DEVELOPMENT TO BUILD FUTURE TECHNOLOGIES

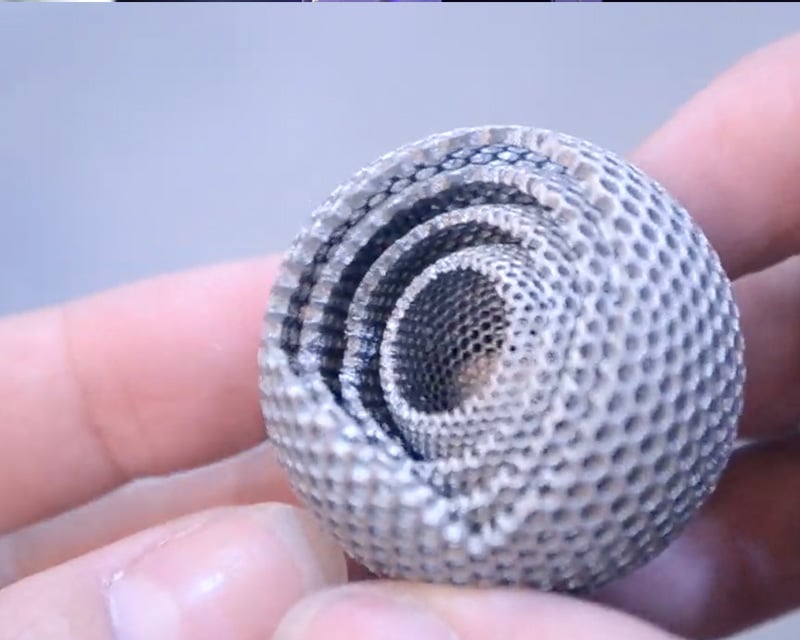

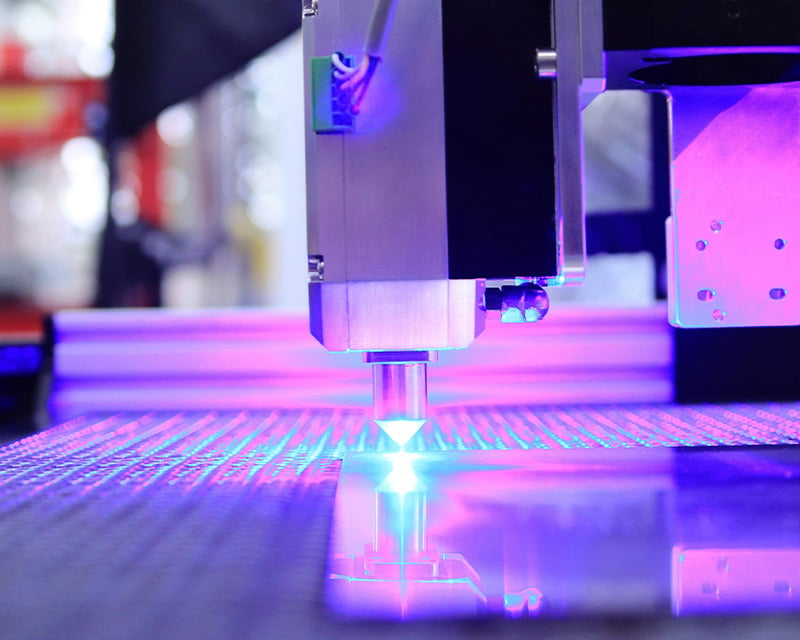

Designed to investigate multiple deposition technologies in a safe and expandable environment, the Materion additive manufacturing laboratory has a variety of additive manufacturing technologies and support for pre- and post- processing.

Building on our strict engineering and environmental controls as well as our Health and Safety expertise allows Materion to develop additive manufacturing capabilities for materials that have never before been developed, including beryllium materials.